All Systems Go: Achieving Integration and Compatibility Among High Tech Manufacturing Building Systems

Published: December 15, 2023

These unique requirements necessitate customized HVAC solutions that are tailored to the specific needs of your manufacturing facility. But how do you ensure that your new HVAC system will work in harmony with your other building systems and equipment—especially when you have different providers for HVAC, lighting and security?

In short, be sure that your HVAC provider has integration and compatibility expertise before embarking upon a costly capital investment. A highly skilled team will be able to connect components and systems for seamless operation.

Integration Support for Seamless Operation

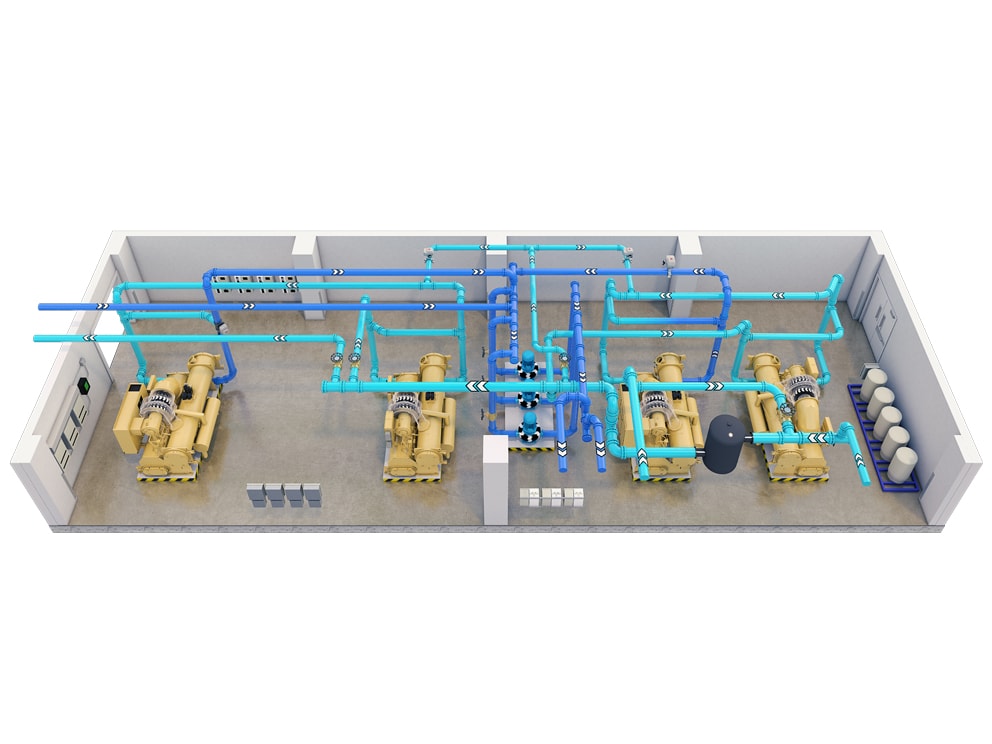

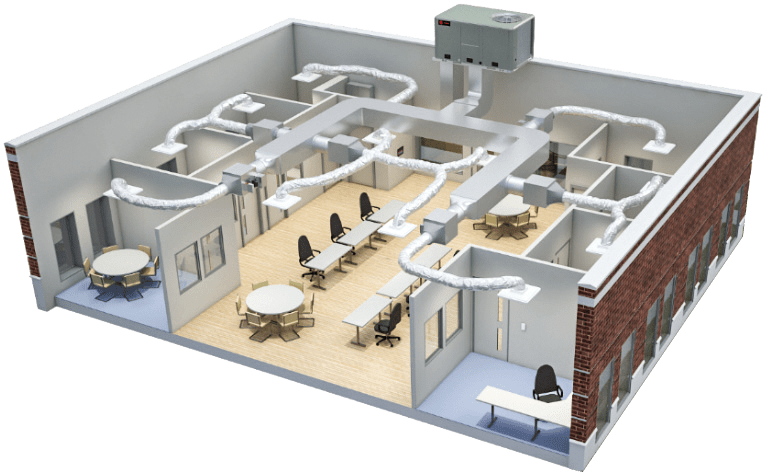

First, a definition. Integration refers to the seamless connection and operation of various components and systems within the HVAC and the overall building infrastructure.

Customized solutions and integration support are essential in designing complex HVAC systems for advanced manufacturing. By collaborating with a highly qualified HVAC system manufacturer, you can develop tailored solutions that meet the specific needs of your facility and ensure seamless integration with other systems. Qualified manufacturers provide valuable integration support, including:

- System Coordination: Ensuring that the HVAC system is coordinated with other building systems, such as electrical, plumbing and automation, for seamless operation.

- Equipment Integration: Collaborating with equipment suppliers and other stakeholders to ensure that the HVAC system integrates smoothly with manufacturing equipment.

- Control System Integration: Implementing advanced control systems that allow for dynamic adjustments and real-time monitoring, enhancing system performance and efficiency.

Ensuring Compatibility and Reducing Conflict

Compatibility refers to the ability of different components and systems to work together without conflict. There are numerous benefits when HVAC manufacturers design for compatibility:

- Smooth Implementation: Ensuring compatibility between various HVAC components leads to a smooth implementation process, reducing delays and unexpected challenges during construction.

- Cost-Effective Operation: Compatible systems work together efficiently and cost-effectively, reducing redundancy and waste.

- Flexibility in Design: A focus on compatibility allows for the selection of the best components from various manufacturers, ensuring the best fit for the specific needs of your high tech manufacturing facility.

- Reduced Maintenance Complexity: Compatibility across systems means that maintenance practices and schedules can be standardized, reducing the complexity of keeping everything in optimal condition.

- Risk Mitigation: Compatibility ensures that all components work together without conflict, reducing the risk of unforeseen problems that might arise from incompatibilities, leading to system failure or inefficiencies.

Collaborating with Manufacturers for Tailored Design

Manufacturers like Trane play a vital role in developing customized HVAC solutions that can be seamlessly integrated with other building systems. Achieving this level of control requires not only a deep understanding of engineering principles but also a collaborative approach, especially in the early design phase.

- Understanding Client Needs: Manufacturers work closely with stakeholders to understand the specific requirements of the manufacturing facility. This includes assessing the environmental control needs, energy efficiency goals, compliance standards and budget constraints.

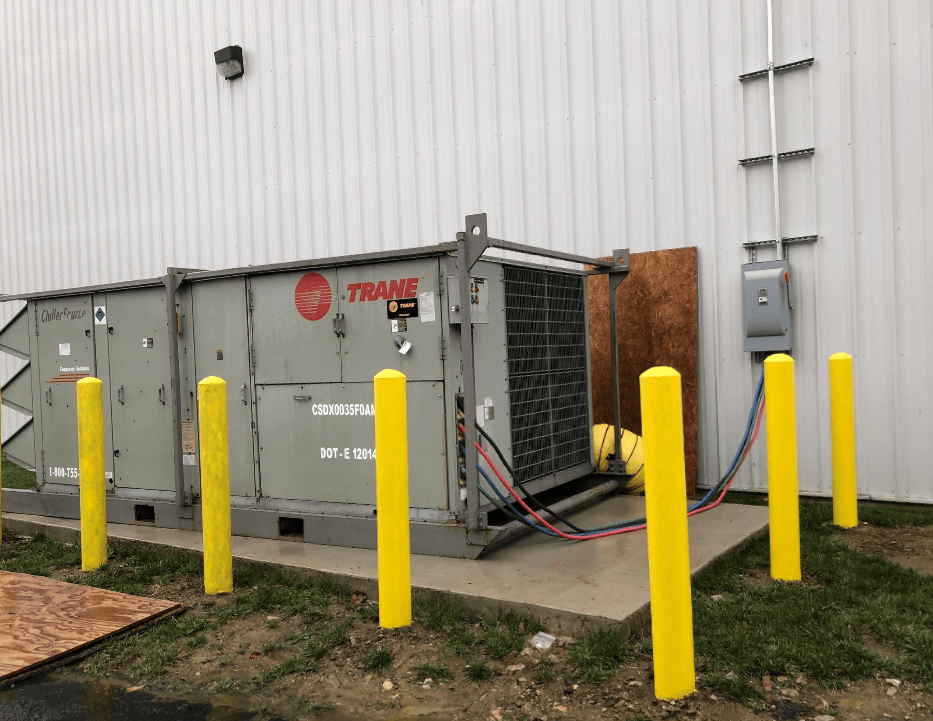

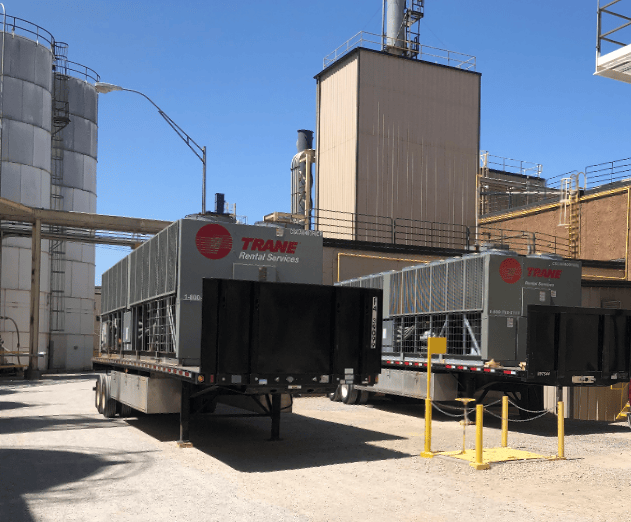

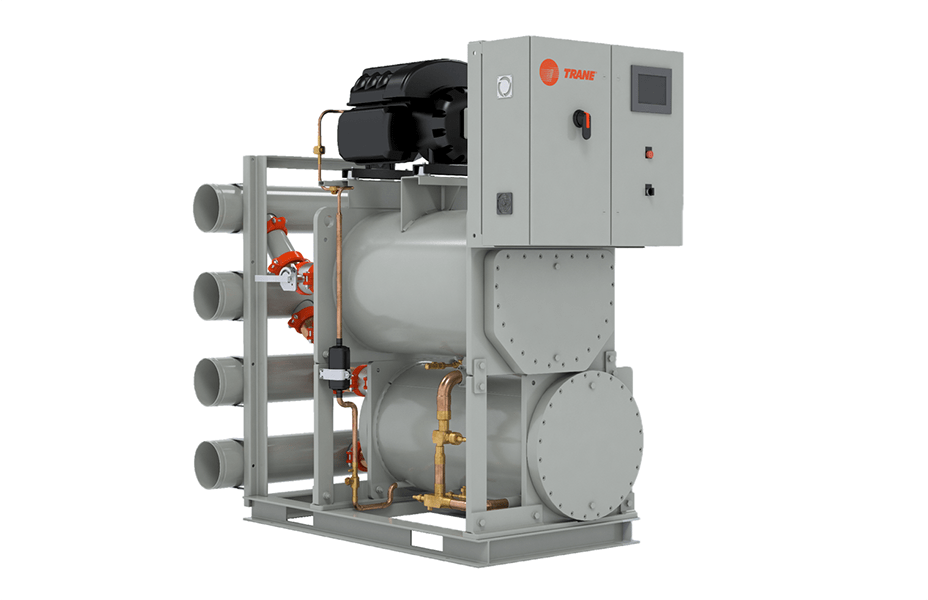

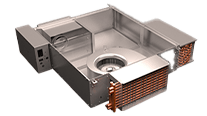

- Developing Custom Solutions: Based on the assessment, manufacturers like Trane can develop tailored HVAC solutions that meet the unique needs of the facility. This may include selecting specialized equipment, designing custom configurations and integrating advanced control systems.

- Providing Technical Support: Manufacturers provide technical support throughout the design and implementation process. This includes providing detailed specifications, performance data and installation guidance.

Integration and compatibility in HVAC equipment and controls for high tech manufacturing—particularly in new construction projects—play a vital role in achieving a responsive, efficient and future-proof environment.

Collaborating with Trane, an industry-leading HVAC and controls manufacturer with decades of integration and compatibility expertise, can help you prevent future compromises, by ensuring you get the most out of all your building systems (Trane and non-Trane) by providing you with a comprehensive and normalized view of your system data.

Looking for customized HVAC solutions and integration support for your next semiconductor or EV project? Contact Trane today to discover how our expertise and innovative solutions can help you achieve success.

Advanced Technology. Climate Sustainability.

Achieving Integration and Compatibility Among High Tech Manufacturing Building Systems

Company embraces high tech and high touch to achieve climate and other goals.

In this Engineers Newsletter (EN), Trane applications engineer, Greg DuChane, shines a light on the evolution, intersection, and future of AI in the HVAC industry.

-

Blog

-

Sustainability

-

Innovation

-

High Tech

-

MacDonald-Miller’s Road to Sustainability

MacDonald-Miller’s Road to SustainabilityCompany embraces high tech and high touch to achieve climate and other goals.

-

Trane Engineers Newsletter: Artificial Intelligence in HVAC

Trane Engineers Newsletter: Artificial Intelligence in HVACIn this Engineers Newsletter (EN), Trane applications engineer, Greg DuChane, shines a light on the evolution, intersection, and future of AI in the HVAC industry.

-

Award-Winning Rockwall County Detention Center Project

Award-Winning Rockwall County Detention Center ProjectWhen Rockwall County, Texas, needed to expand its jail facilities, it turned to the Brandt Companies, Trane and others to get the job done. The team helped build an 83,000 square-foot addition and shepherd it through the state’s rigorous oversight process.