Getting Your Supermarket to Net Zero: A Decarbonization How-To

Grocery Decarb Checklist

Identify opportunities for measurable change

Everyone’s talking about decarbonization these days, and for good reason. Leaders across the grocery industry are responding to a groundswell of pressure from consumers, investors and regulators (not to mention their own children)—by setting emissions targets.

As someone responsible for meeting those corporate goals, you probably have a few questions such as:

- How can I meet emissions targets without sacrificing profitability?

- How do I pay for anything on top of the rising cost of virtually everything?

- Do I have to become an expert at sustainability?

- Where do I even begin?

This article covers those questions and more. It outlines a supermarket-specific four-step plan including funding sources and considerations for your unique business. And it’ll explain why events of the last two years make decarbonization smarter than ever.

It can be tempting to implement changes in an ad hoc fashion, vendor by vendor. While this will deliver carbon reductions here and there, you’ll see the most significant and cost-effective results with a holistic approach. In fact, the only way most supermarket operators will meet their decarbonization goals is with a comprehensive plan that includes emissions benchmarks, clearly defined objectives, scalable solutions and a strategic implementation schedule.

It’s important to note that the grocery industry differs from the general retail sector in several key areas. First, food protection and critical uptime require 24/7/365 energy use. Refrigerants are necessary not only for HVAC, but also for refrigerators and freezers. And the refrigerants used for those refrigerators and freezers are different (often wildly so) from those used in HVAC, and can have varying degrees of impact on climate, efficiency and safety for field personnel. Increasing consumer demand for healthier fresh foods translates to more inventory turns that require refrigeration, transportation costs, inventory investment and increased risk. And, local climate dynamics prohibit the use of a one-size-fits-all approach (for example, stores in Texas and Minnesota have vastly different HVAC-R needs). In addition, with the pandemic-accelerated shift to omnichannel shopping in the last two years, many operators have recognized the need to reconfigure, expand or build new space. The good news is, decarbonization moves can and should happen alongside design, engineering and construction.

So, back to the plan. What does a successful, comprehensive approach look like?

There are four key steps to getting your supermarket buildings to net zero.

STEP ONE: Build a carbon inventory

Shockingly, before you can figure out where you’re going, you have to know where you are. The concept sounds simple—define your current emissions—but in practice this is a complex calculation based on raw data from your utility bills. Benchmarking your carbon footprint requires expert evaluation of three types, or scopes, of emissions:

Scope 1 – Onsite Direct Emissions

Starting at the store level, you need to understand the emissions caused directly by your store operations. Common Scope 1 emissions include natural gas usage, refrigerant leakage and fossil fuel combustion, such as with company-owned transportation or diesel backup generators.

Scope 2 – Offsite Generated Emissions

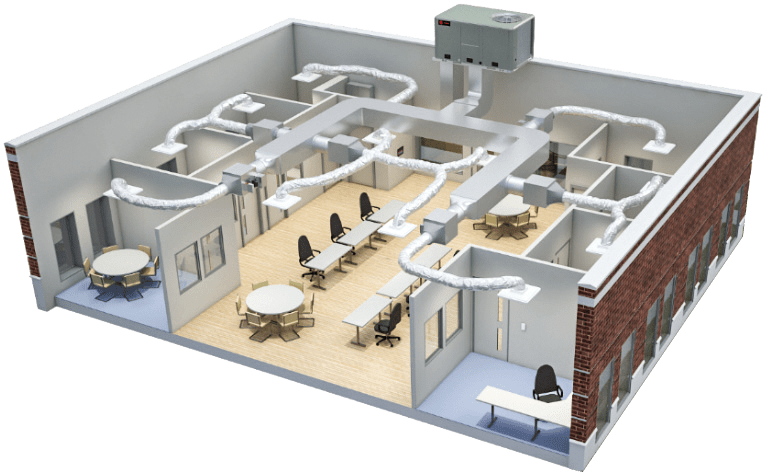

These emissions are generated offsite in the electrical grid. Although Scope 2 greenhouse gases are not physically emitted under your control, you are responsible for the emissions tied to the power you procure. Industry data shows that as much as 70% of supermarket energy use is for HVAC-R and lighting. After reviewing their own numbers, many operators zero in on energy-efficient equipment to reduce emissions as well as operating costs.

Scope 3 – Indirect Emissions

These emissions are indirect, generated by the value chain of your inventory. (Although this is a significant source of carbon and one of high interest to your consumer audience, we will not cover Scope 3 in this article.)

STEP TWO: Set clearly defined objectives

Clearly articulated goals supported by transparent, compelling analysis can help you prioritize spending and get alignment from key stakeholders. We believe there are four levers you can pull to achieve decarbonization:

- energy efficiency

- electrification

- refrigerant choice

- renewable energy

Most likely, you have already taken steps to reduce emissions in one or more areas, so those initiatives and any measurable results to date should be accounted for in your documentation.

STEP THREE: Create a glidepath of solutions

Once you’ve set scalable goals for your stores, you can work with an expert partner to evaluate solutions and create the glidepath that gets you closest to net zero. While projecting carbon reduction across your fleet of buildings may seem daunting, your partner should have the capability to identify decarbonization initiatives and accurately predict the results they will deliver across your portfolio. The good news is that opportunities for carbon reduction can often be opportunities for cost savings.

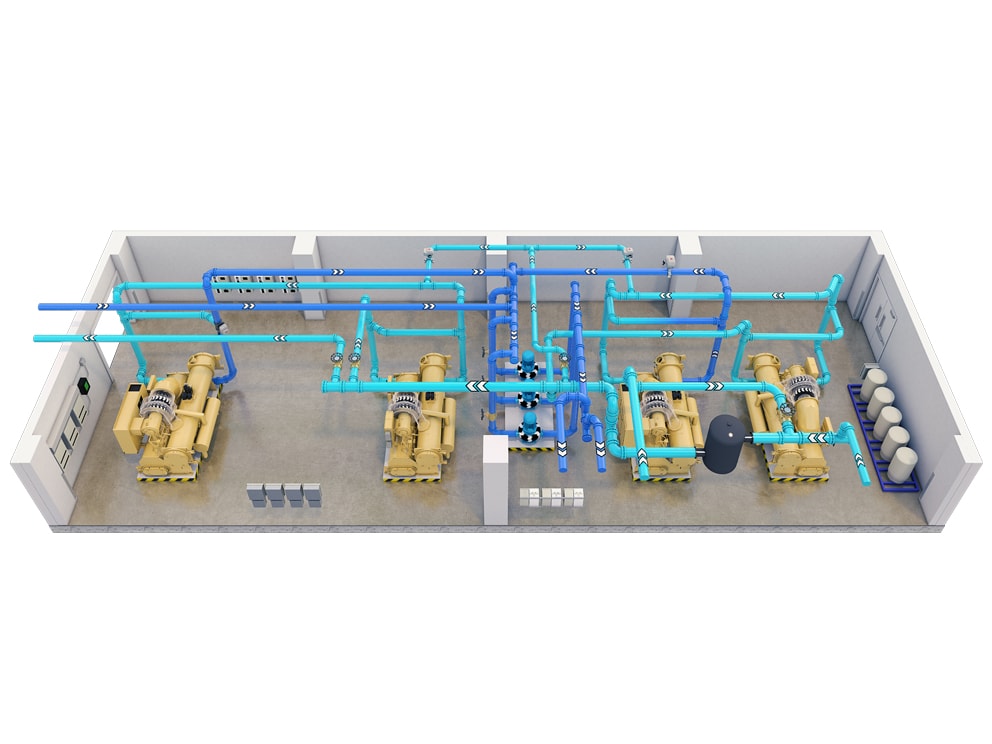

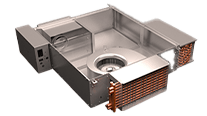

Energy efficiency

If HVAC-R and lighting are your primary energy use, upgrading to energy-efficient HVAC and lighting will deliver measurable reductions in emissions and operating costs. Target fully depreciated equipment for replacement first—before the assets fail—to reduce cost (both in short-term expediting premiums as well as long-term opportunity losses), take advantage of economies of scale and prevent a service event that could release refrigerants into the atmosphere. Another move is to integrate your systems with modern controls. Remote systemwide monitoring and service can reduce carbon-generating truck rolls, increase speed of response and deliver significant savings by improving energy usage, preventing food spoilage and reducing labor costs.

Electrification

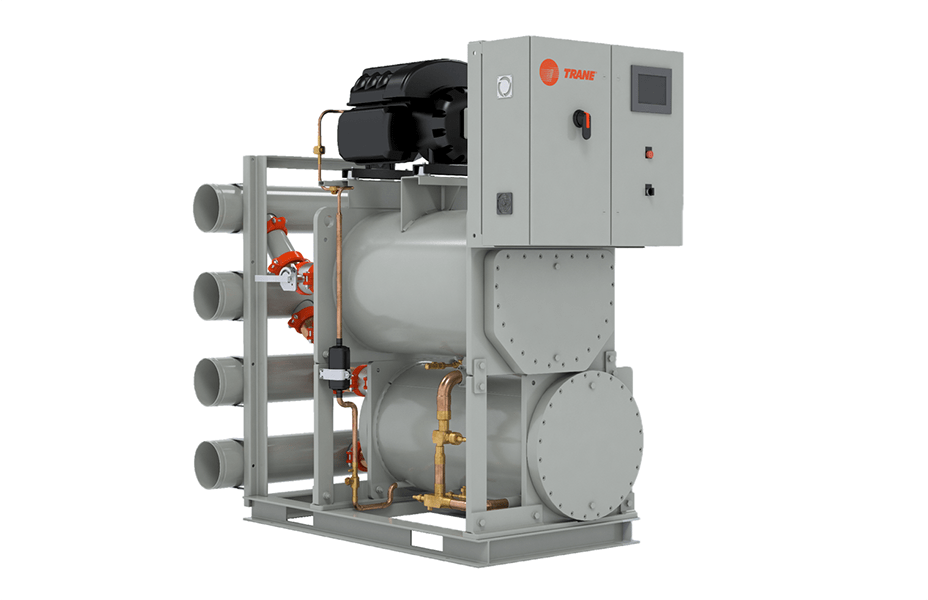

Across the U.S., electricity production is becoming more climate friendly as utilities incorporate renewable sources like solar and wind. Electrifying your heating and cooling operations can reduce operational and energy emissions. Many utility companies are offering attractive incentives and rebates to help pay for upgrades. In addition, by replacing your natural gas boiler systems with high-efficiency electric heat pumps for heating and cooling, you’ll eliminate virtually all direct emissions from your operations.

A word here about your resiliency plan: if a climate disaster knocks out your power, will you be running your refrigeration cases on greenhouse-gas belching diesel generators? Battery backups offer clean resilience.

Refrigerant management

What refrigerants do your chiller and HVAC equipment use—and are they leaking? Older systems, which can leak, may rely on high global warming potential (GWP) hydrofluorocarbons. Multiplex rack systems have averaged operational leak rates of 10-35%*. Replacing high-GWP refrigerants in leaking units is becoming increasingly expensive as EPA regulations requiring specific reclaim protocols strain the supply chain. Additionally, these regulations drive the cost of machine repairs and maintenance even higher. The time to start planning for a refrigerant migration and/or equipment upgrade (to a new machine that can take advantage of low-GWP refrigerant) is now.

Renewable energy

How you procure power is an important element of your transition to net zero carbon. Onsite sources of renewable energy like solar panels will reduce your Scope 2 energy emissions. Offsite sources of renewable energy can be specified through your utility companies’ green energy programs. In the past, this switch came at a cost premium but is now more affordable and in some cases less expensive than traditional power.

STEP FOUR: Implement on a strategic investment schedule

Of course, any evaluation of sustainability solutions for your supermarkets comes back to cost. Even though your decarbonization goals are urgent, you can’t give up your already slim margins. This is where it pays to have a partner who can help you prioritize expenditures, communicate with key stakeholders and identify internal and external sources of funding.

Your investment strategy should begin with an evaluation of equipment life and planned replacement schedules. Every grocery company is dealing with skyrocketing energy and inventory costs, especially in the last few months. Painful as they are, inflationary energy rates actually accelerate the payback period on capital investments for energy efficiency. Replacing equipment now makes sense as you can capture the energy savings right away.

Other financial considerations to discuss with your partner are local energy rates and the effects of recent inflation, setting an internal price on carbon and the emergence of 3rd party institutional financing for decarbonization projects, such as off-balance-sheet solutions. These programs are becoming ubiquitous, freeing up capital for other strategic investments, such as automated fulfillment.

Choose the right partner for sustainable transformation

If you’re feeling overwhelmed, you’re not alone. In a recent survey of sustainability leaders from European and North American grocers, only half of respondents said they were confident they could achieve their sustainability targets. That’s where collaborating with an expert pays off.

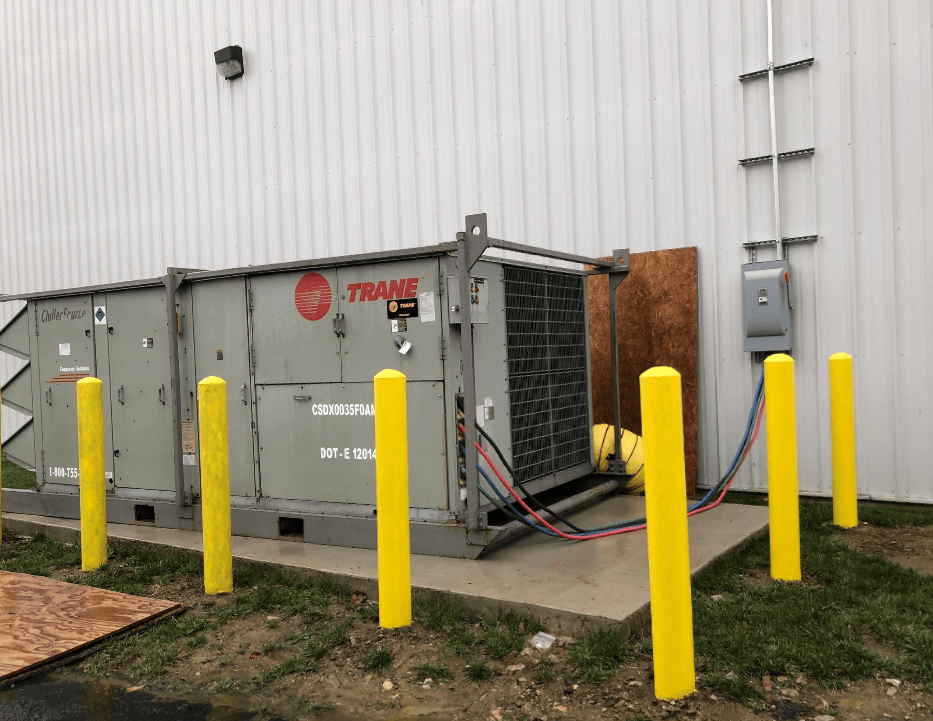

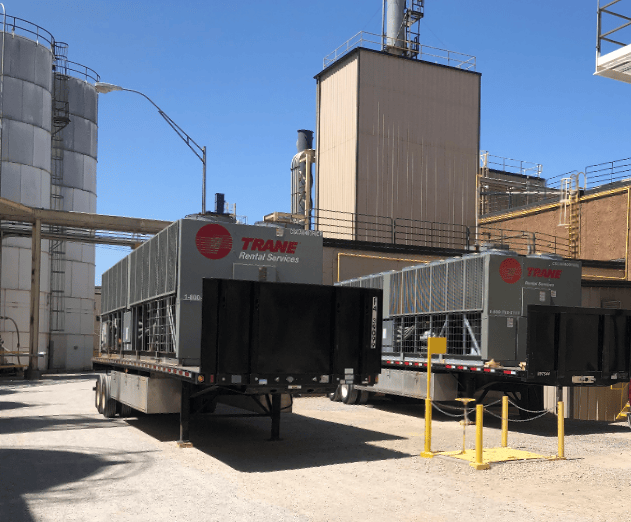

Trane can help you create, finance and execute a comprehensive decarbonization plan. As a member of your sustainability team, we bring a deep understanding of supermarket-specific decarbonization. From specific HVAC upgrades at the building level to systemwide controls and service, our experts will help you achieve your sustainability goals without sacrificing profitability.

So no, you don’t have to become a sustainability expert. You just need to partner with one.

Begin your decarbonization journey today. Connect with a Trane grocery expert to discuss your emissions goals and measurable, financially attractive solutions.

Retail Buildings

Grocery Decarb Checklist Download

About the author

Ethan Kinsey, Sales Leader – Key Accounts

Ethan Kinsey is a sales leader for Trane’s Key Accounts team responsible for the innovation and growth in the Grocery store Vertical Market. In this role, Ethan leads a team of account executives focused on developing programs that provide consistent support of the execution of building expansion across the US and Canada as well as ongoing maintenance and optimization of their customer’s existing building footprint. Ethan has been with Trane since 2007 focused entirely on national program sales in the retail, commercial and industrial sectors. Ethan lives with his family in Sachse, TX and is a graduate of Texas A&M University.