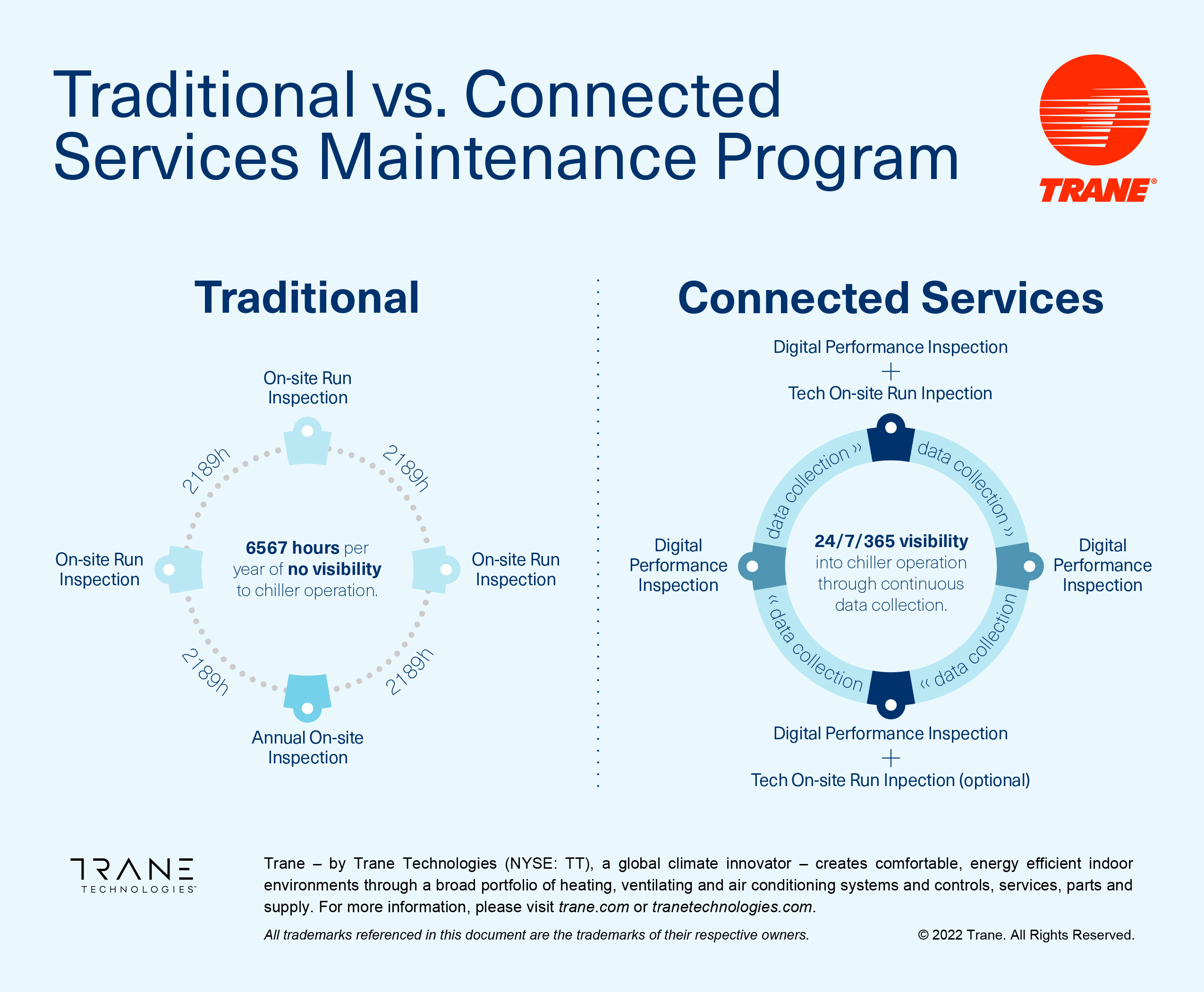

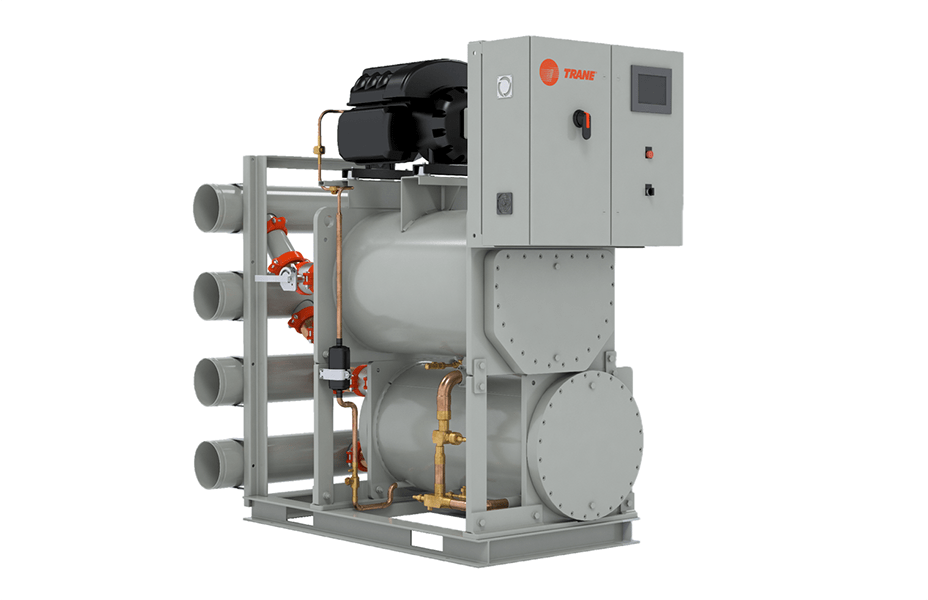

Traditional On-Site Service utilizes on-site inspections to log the chiller operation on that specific day. This standard service method only provides an operational "snapshot in time" analysis. If you are using a typical quarterly inspection schedule, that’s 2189 hours between inspections or 6567 hours/year of no visibility to how your chiller is operating!

A Connected Mechanical Service Agreement leverages continuous data collection since the last inspection through active monitoring and remote access. This method of service captures how your chiller operates at night, weekends, during hot weather and under different loading conditions. You are also provided with 24/7/365 insights, stored for use by your Trane Chiller Technician, which can help you truly optimize your operations, help to save costs, and support your sustainability goals through better chiller performance and quicker problem resolution. Remote access may help to reduce business disruption by allowing your Trane Technician to perform inspections even when chiller is not running. When there is something that needs to be addressed with your system, a Connected Mechanical Service Agreement allows customers to gain priority for unplanned problems and achieve quicker response time using your remote connection. Customers can also support sustainability goals through better chiller performance and quicker problem resolution.