No Margin for Error: Four Ways Precision HVAC Impacts Your High Tech Manufacturing Facility

Published: December 01, 2023

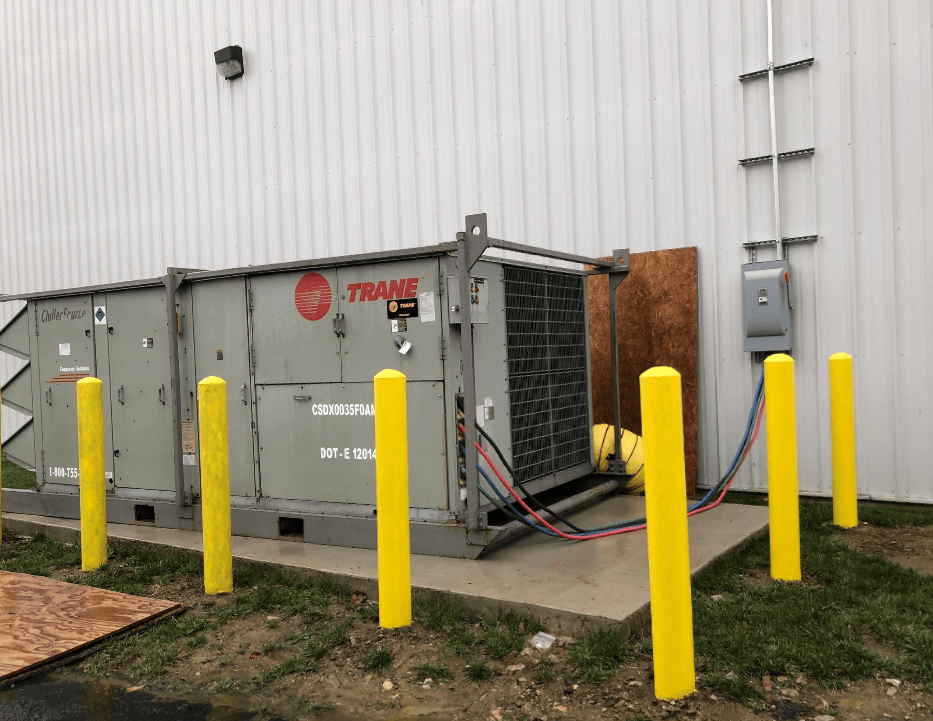

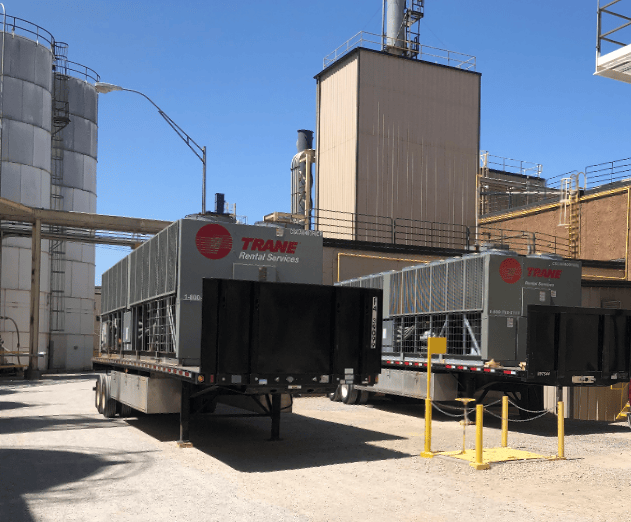

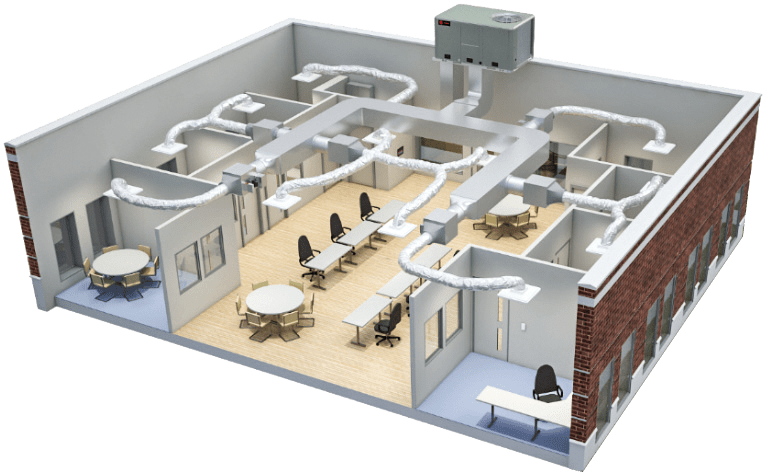

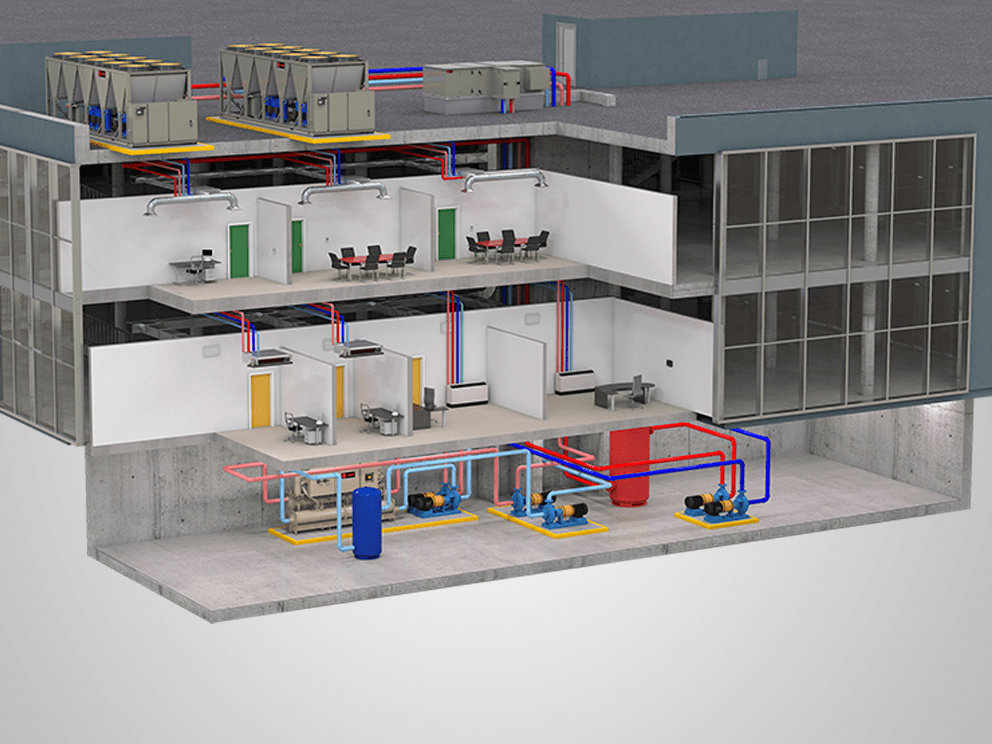

Modern HVAC technologies provide advanced control mechanisms that adhere to exact specifications for temperature, humidity and air quality. Achieving this level of control requires not only a deep understanding of engineering principles but also a collaborative approach that leverages the expertise of HVAC system manufacturers like Trane.

If you’re building new facilities for semiconductor fabrication, electric vehicles or batteries, it’s important to engage with a reputable HVAC partner as early as possible in the design process. Early collaboration results in the most sustainable, cost-effective systems that meet both industry regulations and your unique manufacturing specifications.

This article provides an overview of the role of precision HVAC systems in high tech manufacturing—and how Trane can be a partner to your operation.

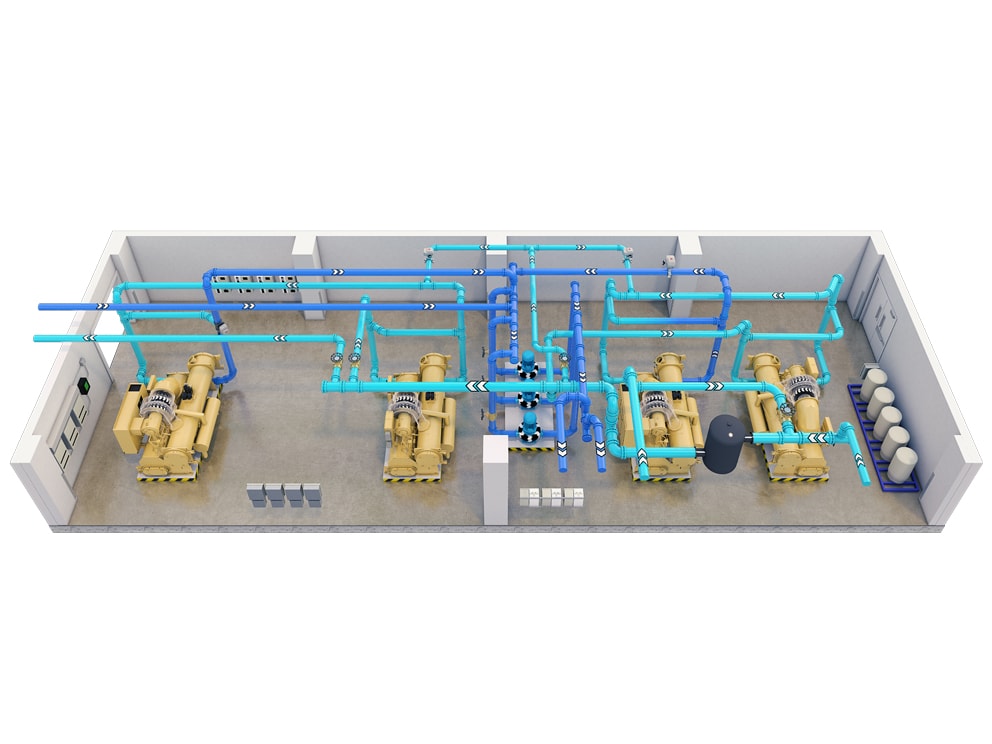

#1 Precision Climate Control

Advanced manufacturing processes require extremely precise, consistent environmental conditions. Maintaining a controlled climate directly contributes to superior product quality, reducing the risk of defects and waste; a stable manufacturing environment also protects sensitive equipment from heat and humidity and keeps it running optimally.

Trane’s impact: We are known for reliable, high-performance HVAC systems that offer stringent control over temperature, humidity and air quality, helping you ensure optimal product quality and reliability. Our dedicated in-house, American tech support team helps ensure field engineers and contractors install and service your equipment properly. Our attention to quality and performance assurance safeguards that your Trane HVAC system consistently performs at its best.

#2 Air Quality Management

Clean, controlled air is vital in high tech manufacturing, especially in cleanroom environments. Air quality is crucial in a high tech production facility for several reasons:

- Equipment Performance: Maintaining good air quality helps prevent the accumulation of dust, particles, or contaminants that can interfere with the proper functioning and performance of equipment.

- Product Quality: Airborne contaminants can have a detrimental impact on the quality of high tech products. Even tiny particles or pollutants in the air can cause defects, contamination, or damage to delicate components during the production process.

- Employee Health and Safety: Exposure to airborne pollutants, such as volatile organic compounds (VOCs) or particulate matter, can lead to respiratory issues, allergies, or other health problems. Providing clean and healthy air promotes a safe and comfortable working environment, enhancing employee productivity and reducing absenteeism.

- Environmental Compliance: Many high tech production facilities are subject to environmental regulations and standards. These regulations often include requirements for air quality control and emissions reduction.

- Process Efficiency: Contaminants in the air can cause clogging or fouling of equipment, leading to increased downtime, maintenance requirements, and reduced productivity. By maintaining high air quality, production facilities can minimize disruptions, optimize workflow, and maximize operational efficiency.

In many areas of the country, wildfire smoke and pollution have stressed air quality management systems. New facilities in particular need HVAC systems designed both to ensure the stringent air quality manufacturing requirements of today and to protect against potential future contaminants caused by climate change events.

Trane’s impact: Our sophisticated filtration and monitoring systems help minimize particulates and contaminants, ensuring an environment that meets or exceeds required standards and contributes to a high-quality production process.

#3 Compliance and Certifications

Many advanced manufacturing processes are subject to strict industry regulations. HVAC solutions should be designed with ongoing compliance in mind, ensuring that indoor air systems not only meet but often exceed regulatory requirements.

Trane’s impact: Our systems maintain precise control over indoor environmental quality—the key to ensuring that your manufacturing environment aligns with established regulations for quality and safety. We can help you achieve and maintain certifications that enhance your brand's reputation and foster trust with customers and regulatory bodies.

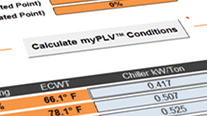

#4 Leveraging Data for Continuous Improvement

Smart HVAC systems can collect and analyze data and provide actionable insights for continuous improvement. Partnering with a manufacturer who follows a data-driven approach enables proactive ongoing adjustments, optimizing both performance and efficiency.

Trane’s impact: We are an industry leader in smart controls, building automation systems and services that deliver data to enhance decision-making, facilitate predictive maintenance and promote a culture of continuous improvement—ultimately contributing to overall operational excellence.

Beyond Temperature – A Strategic Partner in Quality Management

In an industry where quality cannot be compromised, Trane's innovative, sustainable HVAC solutions offer a comprehensive approach to environmental control. Consult with Trane experts as early as possible in the design process for your new facility. Our commitment to precision, quality and data-driven insights ensures that your HVAC systems are not just about heating and cooling, but are integral to the success of your manufacturing process.

To start a conversation about how precision Trane HVAC can help ensure superior product quality in your high tech manufacturing facility, contact a Trane expert today.

Advanced Technology. Climate Sustainability.

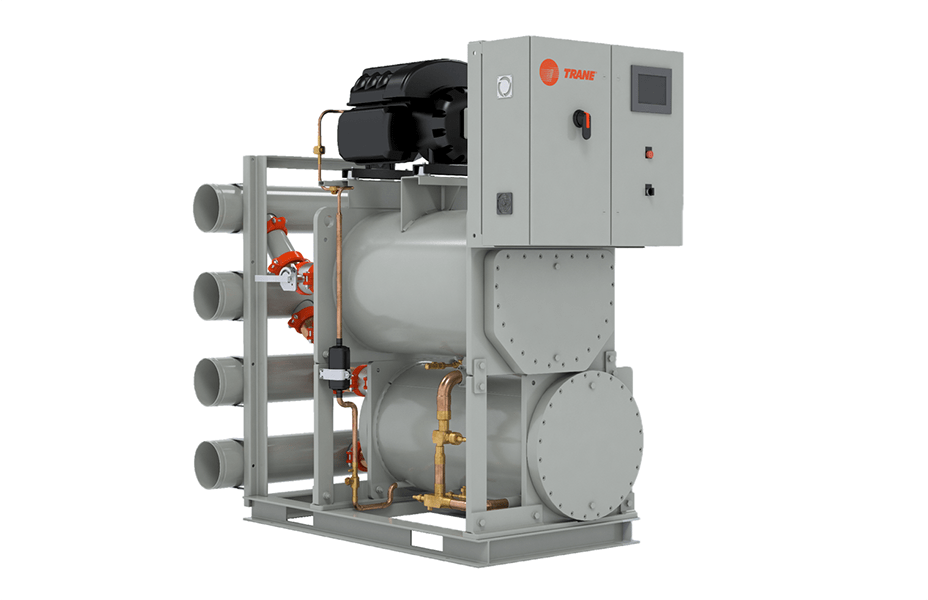

Innovative process cooling for high tech manufacturing.

Explore the evolution of mechanical services, from traditional maintenance to a connected approach, enhancing reliability, reducing costs, and extending equipment lifespans.

When you connect buildings, equipment, systems, and operations, you connect possibilities.

-

Blog

-

Air Quality

-

IEQ

-

Connected Buildings

-

High Tech

-

The Evolution of Mechanical Services: A Connected Approach for the Future

The Evolution of Mechanical Services: A Connected Approach for the FutureExplore the evolution of mechanical services, from traditional maintenance to a connected approach, enhancing reliability, reducing costs, and extending equipment lifespans.

-

Unleash the Power of Smart Buildings with Trane

Unleash the Power of Smart Buildings with TraneWhen you connect buildings, equipment, systems, and operations, you connect possibilities.

-

How to Absorb a New Standard: ASHRAE® 241 and More

How to Absorb a New Standard: ASHRAE® 241 and MoreCOVID-19 brought Indoor Air Quality (IAQ) to the forefront, yet the lack of established standards caused confusion and ineffective measures taken. ASHRAE stepped in, releasing Standard 241 to provide comprehensive guidance on ventilation and IAQ, optimizing indoor environments and reducing disease transmission.