- Agility magnetic bearing water-cooled chillers feature a third-party verified Environmental Product Declaration and operate with low-GWP refrigerant R-513A

- A direct drive, oil-free, multi-stage magnetic bearing centrifugal compressor with permanent magnet motor offers stable operation across varied conditions

- Compact design fits through standard 72″ x 80″ double doors and can easily be disassembled into two sections for 34″ x 80″ single door access, reducing installation time and costs

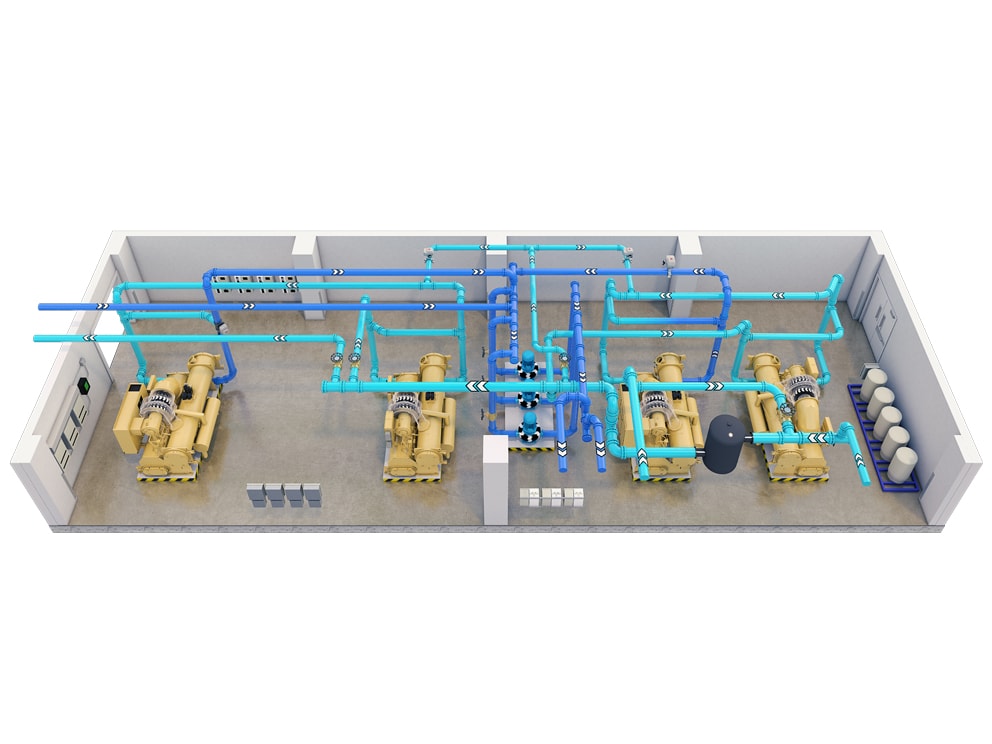

- The Agility magnetic bearing water-cooled chiller is a part of the Comprehensive Chilled Water System, which delivers high-performance cooling while reducing initial costs

- Symbio 800 serves as a launch point to connect to an array of Trane systems and services

- Tracer® SC+ building automation system features pre-engineered Chiller Plant Control, enhancing the rotation, staging and sequencing of multiple units to meet dynamic building loads.

- Available options and system enhancements include heat recovery, thermal energy storage, harmonic filters, belzona coating and marine waterboxes

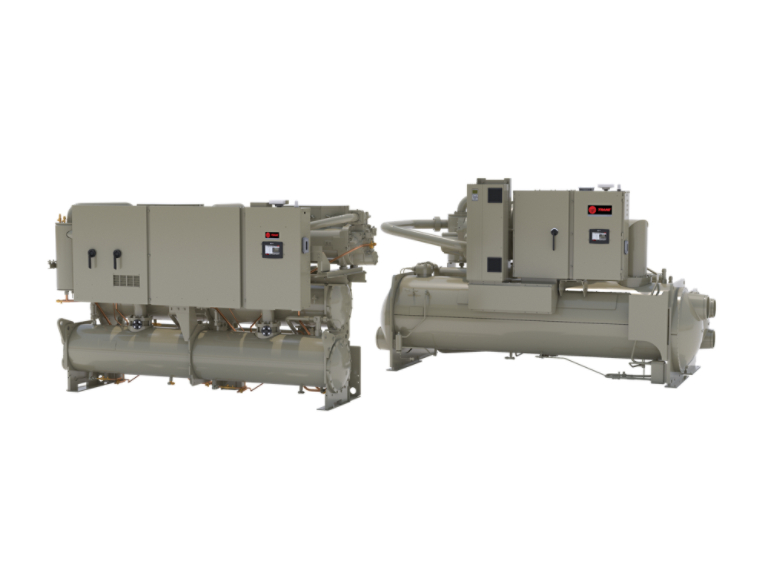

Agility® Magnetic Bearing Centrifugal Chiller

Model HDWA

Overview

Compact size without compromise.

The Trane® Agility magnetic bearing centrifugal chiller offers a compact, efficient, and sustainable thermal management solution. Ideal for new construction and existing buildings, the Agility chiller helps lower installation costs while modernizing system performance and versatility.

- Capacity Range: 175-500 tons; 2,100-4,900 MBH

- Refrigerant: R-513A

- Compressor Type: Centrifugal, Magnetic Bearing

- Medium Pressure

- Controller: Symbio® 800

-

Energy-Efficient Operation

With full-load and Integrated Part Load Values (IPLV) that outperform the ASHRAE® 90.1-2022 standard, the Agility magnetic bearing water-cooled chiller helps reduce electrical consumption and demand charges, contributing to lower operating expenses. The chiller’s control logic coordinates the compressor’s motor speed and inlet guide vane position to maintain the chilled water setpoint. At AHRI conditions, some units can unload down to 10% of design tonnage with constant entering water temperature, delivering efficient performance even at lower loads.

-

Performance Backed by Trane

The Agility magnetic centrifugal chiller features an oil-free, two-stage centrifugal compressor with a permanent magnet motor for stable operation across a wide range of operating conditions. An onboard Uninterruptible Power Supply (UPS) protects components during power interruptions, and Rapid Restart™ helps bring the chiller online within 45 seconds after power is restored, ramping up to 80% of the chiller's design capacity in under 4 minutes. The Symbio® 800 controller enables secure connectivity and integration with building automation systems. Backed by Trane, factory-available extended warranties with full coverage of up to 10 years offer additional long-term peace of mind.

-

Space-Saving Design, Cost-Effective Installation

The Agility magnetic bearing water-cooled chiller fits through standard double doors (72-inch by 80-inch) fully assembled and can easily be disassembled into two sections for single-door access (34 inch x 80 inch). This reduces the need for structural modifications, cutting installation time and costs.

-

Reduce Your Environmental Footprint

Our focus on decarbonization has helped advance the industry with the Agility model HDWA’s third-party verified Environmental Product Declaration. Agility chillers use low-GWP refrigerant R-513A, offering a 55% reduction in global warming potential compared to R-134a. Agility also features various design options, including harmonic filters, heat recovery, and thermal energy storage for flexible operation to help manage peak demand. These system enhancements help building owners meet sustainability goals while reducing environmental impact.

Product Information

- Capacity Range: 175 to 500 tons

- Refrigerant: R-513A

- Heat Recovery: Available options for integrated heat recovery up to 130°F (54°C)

- Compressor Type: Direct drive, oil-free, multi-stage magnetic bearing centrifugal compressor

- Equipment Controller: Symbio 800 for connectivity to Trane systems and services

Product Literature

Installation Operation Maintenance (IOMs)

Environmental Product Declaration

FAQs

Your questions about the Agility® Magnetic Bearing Centrifugal Chiller, answered.

The Agility chiller is available from 175 tons - 500 tons, with projects in place to offer it up to 800 tons.

Yes! Agility has available options for integrated heat recovery up to 130°F (54°C). Please contact your local Trane Representative for more information.

As standard, the chiller’s motor voltage is 460V/480V. However, Agility’s advantage is that customers can utilize existing power without sourcing, wiring, and installing a separate 208V or 575V/600V transformer.

Yes! The Agility chiller with bolt-together design balances size and efficiency, fitting through a standard double door (72-inch by 80-inch) fully assembled and can easily be disassembled into two sections that fit through a single door (34-inch x 80-inch), reducing installation time and costs.

The Agility chiller features an oil-free, two-stage centrifugal compressor with a permanent magnet motor for stable operation across a wide range of operating conditions.

Agility’s compressor utilizes magnetic bearings, which allow it to operate at higher speeds, eliminating the need for gears.

Agility chillers use low-GWP, medium-pressure refrigerant R-513A, offering a 55% reduction in global warming potential compared to R-134a. Benefits of using medium pressure refrigerant include high efficiency, high reliability, and low leak rates. With less refrigerant volume, medium pressure refrigerant also allows Agility to have a smaller footprint compared to chillers using high-pressure refrigerants.

A magnetic bearing chiller uses electromagnetic fields to suspend and stabilize the compressor shaft, avoiding direct contact between moving parts. This technology allows the compressor to operate without oil for lubrication.

One of the major advantages of magnetic bearings is their ability to handle higher speeds. Rolling elements and hydrodynamic bearings have upper limits when it comes to speed, but magnetic bearings allow these limits to be significantly increased. Higher speeds can be advantageous for compressor designers because increasing the impeller's speed allows for a smaller impeller, resulting in a more compact compressor and chiller. Using magnetic bearings also eliminates oil systems, removing the need for oil in the chiller.

Looking for parts?

Discover More of What’s Possible with Trane

-

HVAC Design and Analysis Tools

Backed by Trane's long history of HVAC system design and software simulation knowledge, our cutting-edge HVAC tools and calculators answer your challenges and help create a more sustainable world. -

Advance your mission with Trane as your dedicated partner in creating lasting improvements for your people, facilities, and future.

-

Building Decarbonization Solutions

The journey to decarbonize your building is uniquely yours and Trane can meet you at any point. Whether policy, regulations or your own ESG goals are motivating your building to change, Trane has the answers. -

When electrification of heat becomes part of your building’s decarbonization journey, contact your Trane office. We can support you every step of the way.

-

Enhance your buildings performance with Trane’s innovative building control solutions, designed for both modern and previous systems to improve comfort and reduce energy consumption.