According to a recent study, more than half of global data centers have experienced an outage in the past three years. Nearly 16% of these operators suffered losses of more than $1 million1. While power issues remain the primary cause of data center downtime, cooling problems account for nearly 20% of all outages2.

So, what can you do to make sure your HVAC system is reliable as possible?

First, make sure your HVAC system is as smart as the rest of your operations.

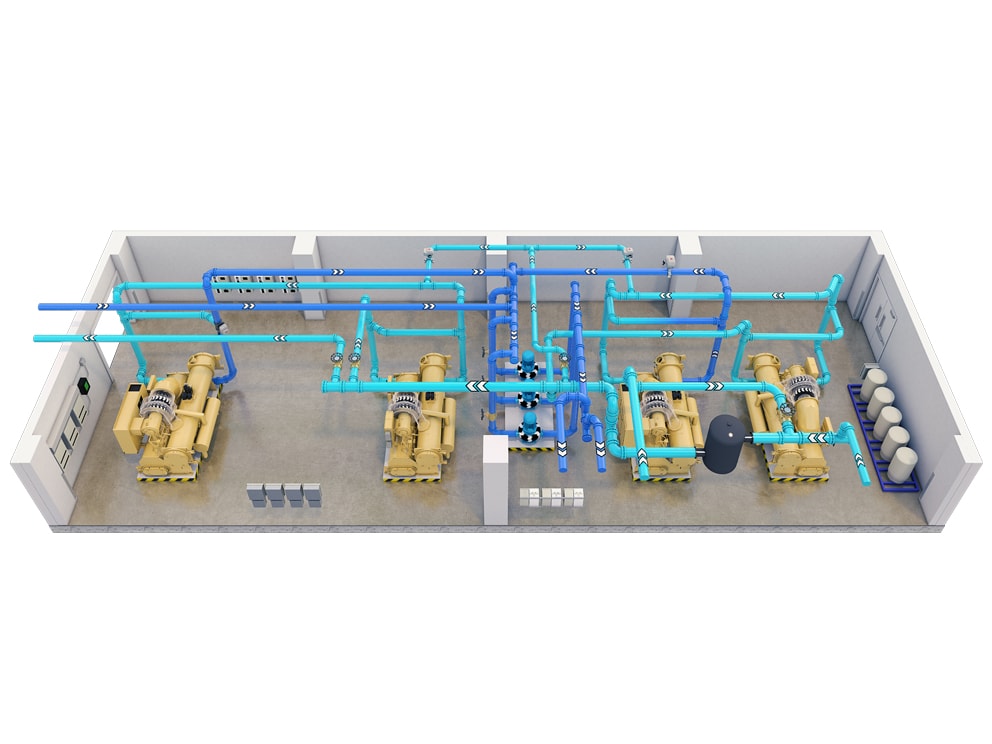

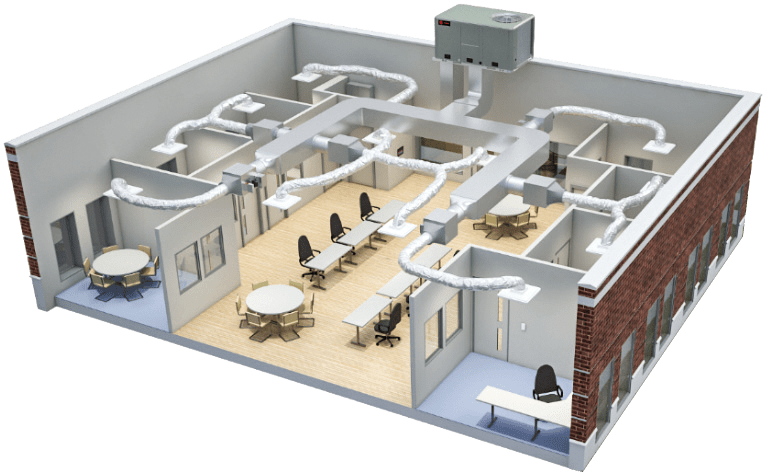

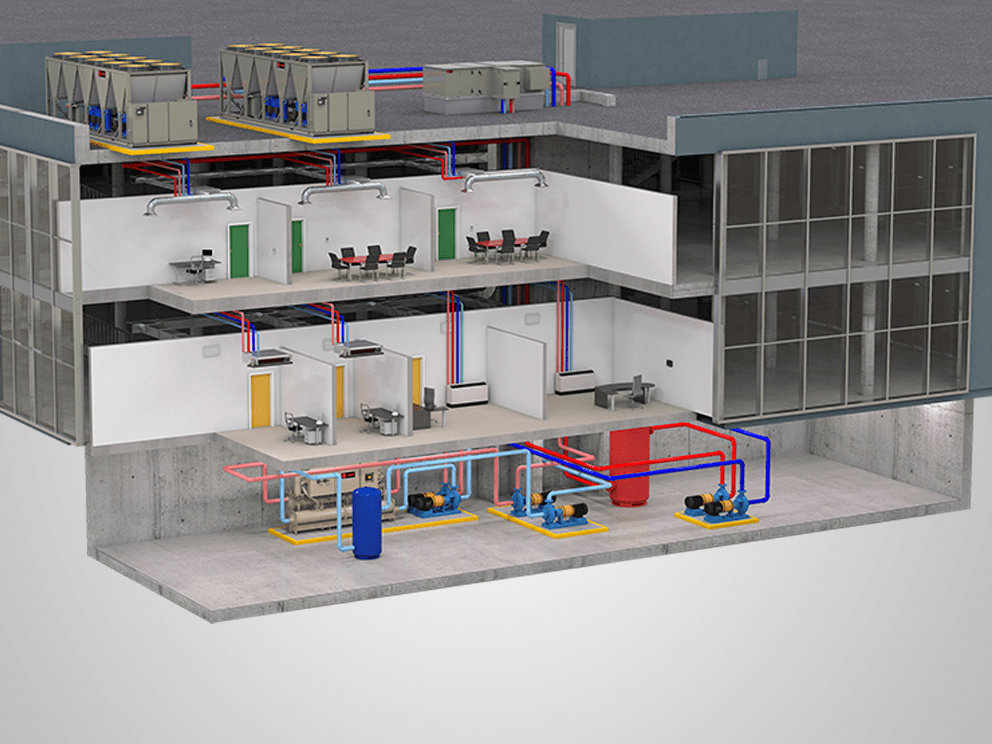

Like all technology, HVAC equipment and controls continuously evolve. Are you using the most advanced system you could be? An advanced, robust HVAC system operates as a single computer networking unit, controlling and monitoring building-wide assets. At its most basic there are 3 key components:

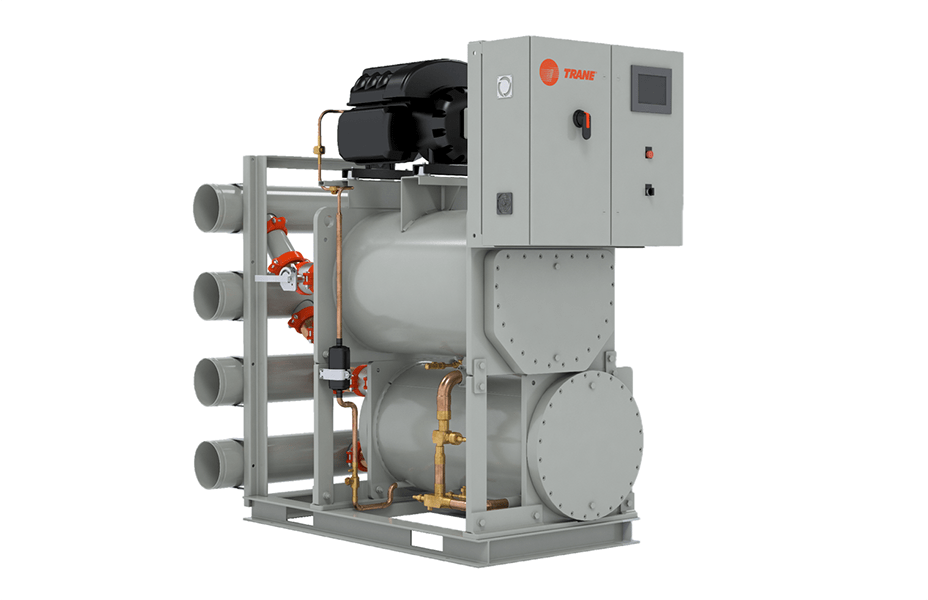

- Energy Efficient HVAC Equipment that is built to operate in always-up, always-on settings

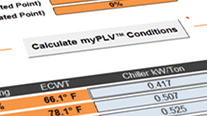

- Advanced Equipment Controllers that receive data from sensors in the equipment and determine how the HVAC should respond. Latest gen equipment controls can support a range of industrial communications protocols like Modbus, BACnet, with the ability to integrate into Programmable Logic Controllers (PLCs) and Data Center Infrastructure Management (DCIM) systems.

- Intuitive User Interfaces like online dashboards or apps that empower users to interact with the HVAC system and view equipment health reports

Then keep it up and running by establishing a rigorous maintenance program

The robust data collected by an advanced equipment controller can tell you not only about your current state, but also help you identify and fix issues before they affect your operations.

Many data centers like yours rely on Connected Services from Trane to monitor their system’s health and performance, watch for anomalies and detect problems early. When an issue is identified, we’ll fix it remotely when we can or notify you if further action is needed based on the guidelines you establish as a part of your service relationship.

Our specialists examine details within your HVAC system to anticipate potential failures. For example:

- Fluids and Lubricants—We extract oils, refrigerants and solutions from an HVAC system and analyze them in a specialized chemical laboratory. This enables us to evaluate your system’s health and provide maintenance based on the results.

- Vibration Analysis—Trane uses handheld vibration analysis tools to collect recordings quickly. Then we send them to the cloud for machine-learning-enabled diagnostics and receive results in near-real time. Ultrasonic listening devices help us “hear” potential leaks and system anomalies—one of the most effective ways to detect imminent system failure.

- Advanced Diagnostic Tools—Electromagnetic induction helps us identify tube wear and possible future failure in chillers and other thermal systems. Infrared thermography uses digital imaging to spot abnormal thermal conditions inside high-speed equipment, electrical panels and heating and cooling equipment.

While HVAC-related issues rank among the least common causes of data center downtime3, they are arguably among the most preventable. Unlike network connectivity glitches or power failures stemming from third-party providers, you have significant control over your data center's cooling infrastructure.

Take proactive measures now to safeguard, optimize and ensure the smooth operation of your cooling infrastructure, maximizing uptime for the benefit of both your customers and your company's bottom line.