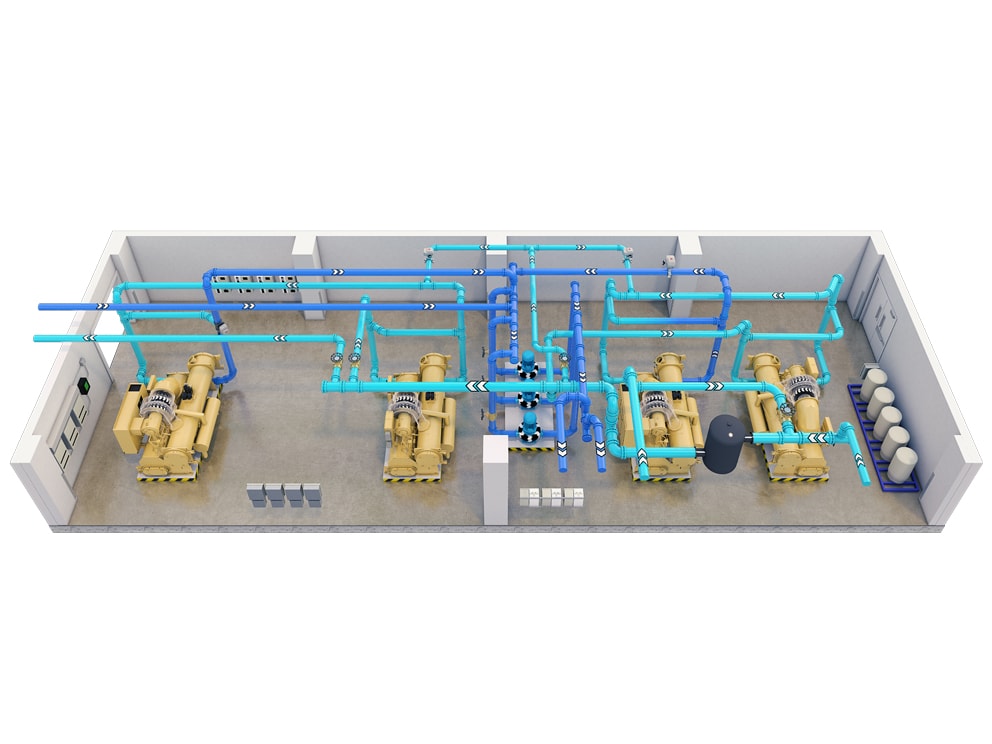

Trane – by Trane Technologies (NYSE: TT), a global climate innovator, has introduced new innovations to provide outdoor heat pump technology to multi-zoned buildings, optimize indoor environments, and empower customers to start their transition to next-generation refrigerants.

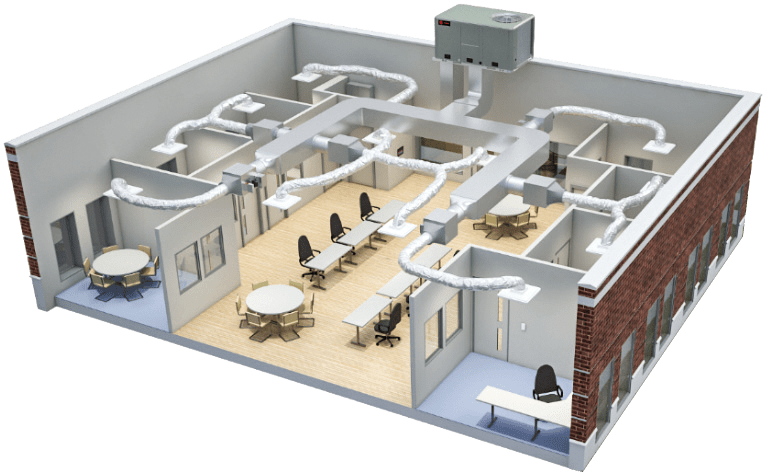

- Mitsubishi Electric Trane HVAC U.S. (METUS) has expanded the Trane® / Mitsubishi SMART MULTI® line to include 6-, 8-, and 10-ton outdoor units ideal for light commercial buildings with space constraints.

- The new Synexis® Sentry XL joins the Synexis family of air and surface purification solutions, providing air purification and surface cleaning in occupied spaces up to 3,000 square feet.

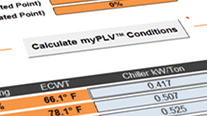

- The company is transitioning its IntelliPak® and Voyager® lines of packaged rooftop units to A2L refrigerants as part of Trane Technologies’ climate commitment.