Click here to see the video case study about Katy Medical Plaza

Challenge

An industry innovator, Jacob White Construction, is known for its high performance building construction and commercial real estate development across the country. As owner and general contractor for the Katy Medical Plaza, the firm sought to develop a next generation medical office complex constructed with the highest standards; one that would meet LEED certification requirements, offer low operating costs and provide optimal indoor air quality.

“It’s not that I’m a big proponent of LEED; it’s more that I’m a proponent of high performance buildings, and LEED gives us something to measure it by,” said Jeff Mickler, president, Jacob White. “High performance, meaning really quality air inside and low operating costs, is our main goal for these buildings."

Jacob White selected J & S Mechanical, a design/build mechanical contractor in business for more than thirty years, as their partner on the Katy Medical Plaza project. “From a mechanical standpoint the biggest challenge of the Katy Medical Plaza building was designing the building for the LEED certification, which includes the ventilation effectiveness and overall sustainability of the mechanical systems,” said Jay Gabrhel, J & S Mechanical, president. “We needed systems that were going to come on every morning at 6 o’clock, reach cooling capacity in a very short duration, shut down in the afternoon and come back on the next day. We just cannot afford failures, period.”

Solution

Based on a long-term relationship with the LEED accredited professionals at Trane, J & S Mechanical selected the company to partner with them on the mechanical design work and equipment for the building. “Trane has been one of our primary suppliers since our company has been in business in the Houston market,” said Gabrhel. “We found, over the course of the years, that Trane seems to be the most responsive, not only from a design/build standpoint but also from an engineering and support standpoint.”

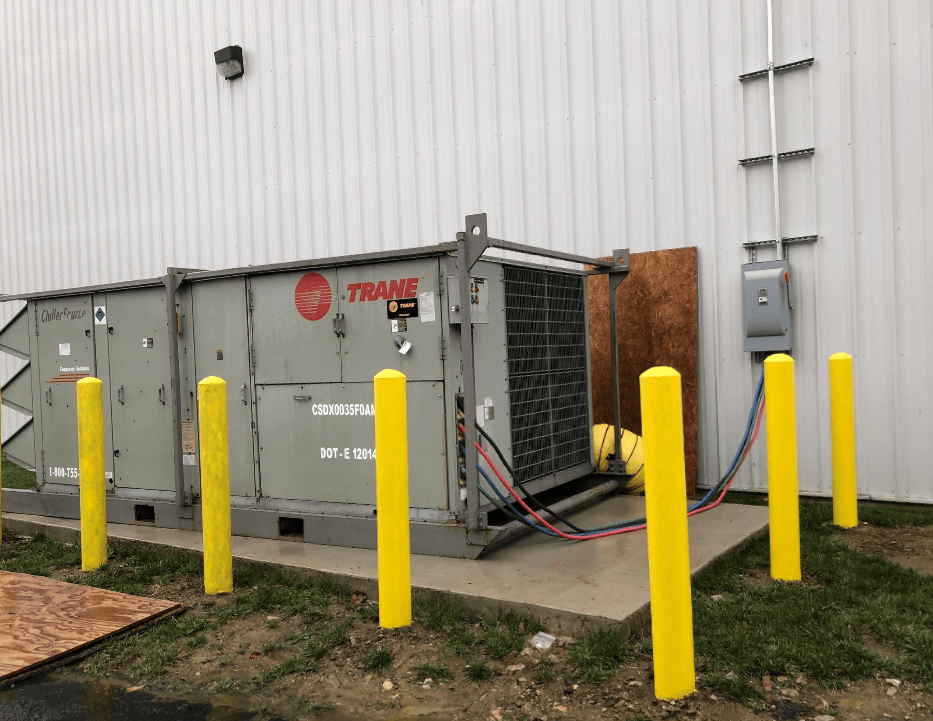

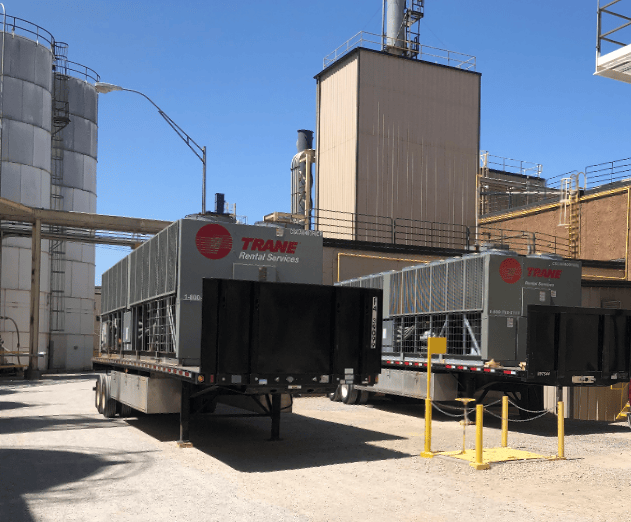

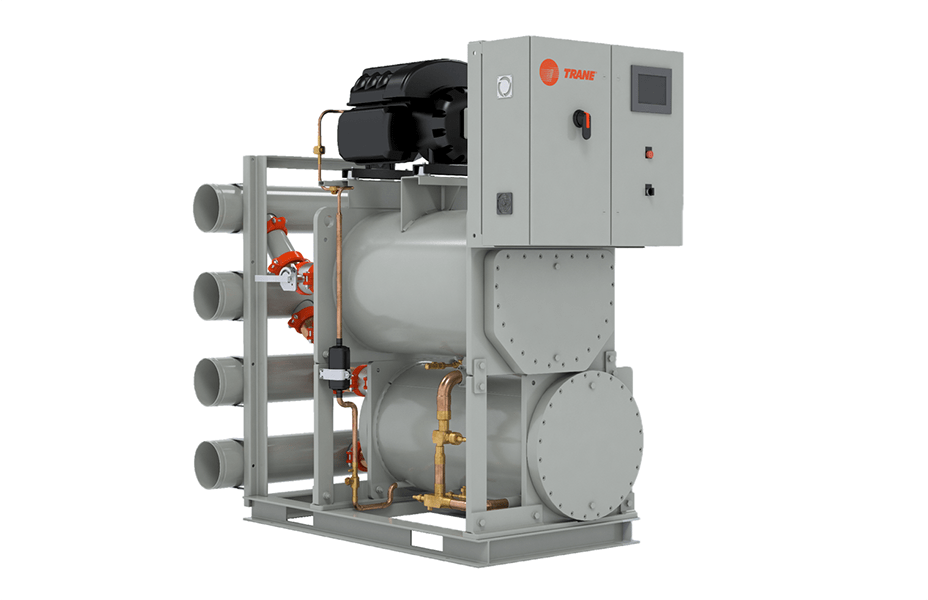

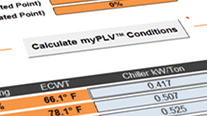

Incremental capacity for comfort and efficiency A Trane 140-ton air-cooled RTAC chiller was selected for the new building. The RTAC screw chiller includes 60-ton and 80-ton compressors, offering dual circuit,stand-alone incremental capacity to keep tenants comfortable during peak and off peak demand periods, while maintaining efficiency. The chiller’s patented unloading system allows the compressor to exactly match building loads to reduce electrical usage.

The RTAC air-cooled rotary chillers are engineered for low life cycle costs and reliability through design simplicity. With only two moving parts on the system’s Helirotor™ low speed, direct drive compressors, the chillers provide high reliability and meet ASHRAE 90.1 efficiency requirements.

Optimizing indoor air quality

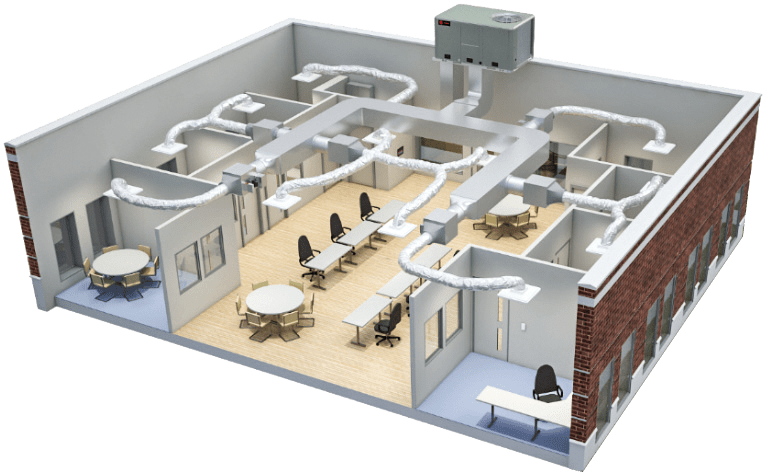

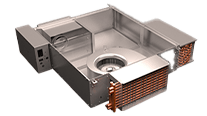

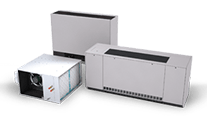

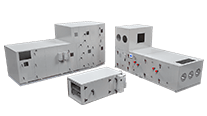

Critical for the productivity and well-being of building occupants, indoor air quality is particularly important to the medical-related tenants of the Katy Medical Plaza. To ensure that their stringent standards are met, a Trane Performance Climate Changer™ was installed on the roof and configured to provide and treat 100 percent outside air coming into the building if needed.

The Performance Climate Changer delivers optimal ventilation throughout the building to keep tenants comfortable. The system incorporates Merv 13 filtration and requires a minimum of 35 percent fresh air to keep CO2 levels less than 400 parts per million. Supplying air at a constant, low dew point temperature at all load conditions, the Performance Climate Changer dehumidifies the outside air to reduce humidity levels to 45 percent to 50 percent for comfort and avoidance of mold or bacteria issues.

Results

Jacob White Construction, J & S Mechanical and Trane have completed the first of three identical buildings, which will comprise the new Katy Medical Plaza. The building, 94 percent leased to doctors and other medical professionals, has achieved the objectives established for a high performance, LEED certified building, providing healthy indoor air quality, low operating costs and energy efficiency.

“The incremental capacity on the Trane screw chiller goes a long way toward keeping our energy usage down,” said Jay Gabrhel, president, J & S Mechanical. “With the Trane mechanical system and the tight construction of the building, we are enjoying approximately 40 percent to 50 percent savings in energy compared to a similar size building here in the Houston market.”

“Our tenants care most about operating costs, indoor air quality … and they don’t want to be hot,” said Mickler. “If we can increase comfort and provide healthy air quality, their people are happier and their productivity goes up at least 5 percent. They can definitely see the financial benefits.”