Project Highlights

Location: Bellevue, Washington

Industry: Commercial Real Estate

Products Used: Chillers,

Services Used: Upgrading,

Climate: Humid & Cold

Topic: Efficiency, Cost-Saving, Optimal Comfort,

Challenge

As Kemper Development Company made plans for the expansion of its two-tower Lincoln Square South development, the property owners outlined their objectives to improve the energy efficiency of their mechanical systems, while remaining budget responsible. The company sought the guidance of a contractor, with large project experience, who they could trust to protect their best interests.

Solution

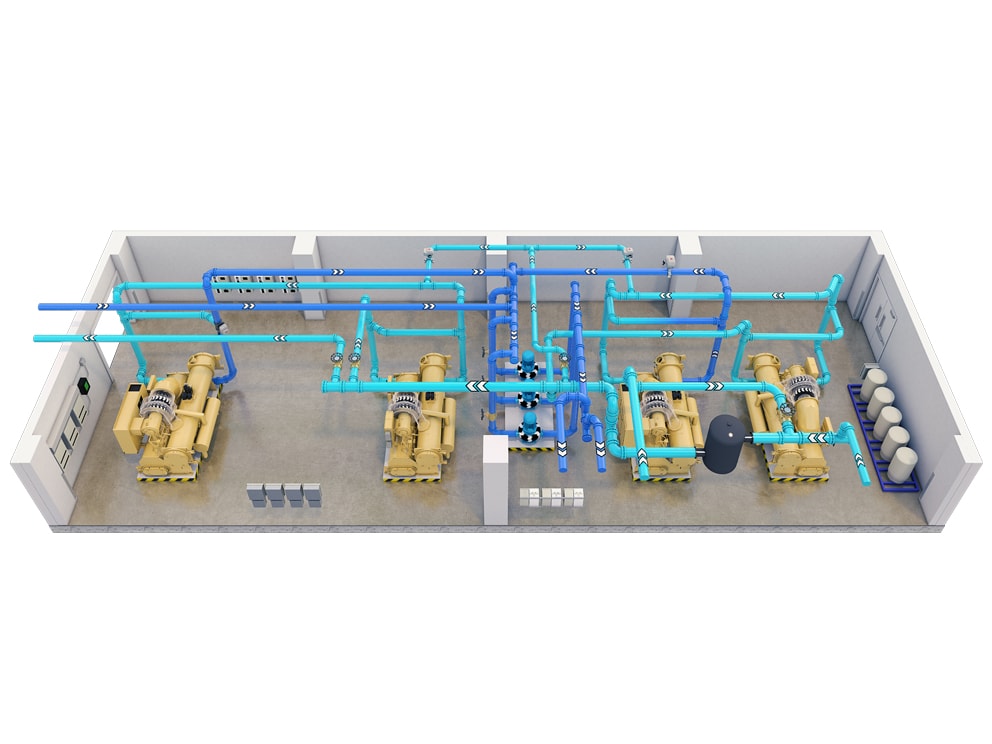

Based on a relationship that spanned more than thirty-five years, Kemper Development Company contacted MacDonald Miller Facility Solutions, a full-service design-build mechanical contractor operating in the Pacific Northwest. After evaluating the needs of the property, MacDonald Miller suggested a central plant to consolidate Lincoln Square’s mechanical footprint and improve efficiency. The mechanical contractor selected Trane to partner with them on the project based on the company’s knowledge, broad product offering, and Kemper Development Company’s familiarity with Trane’s reputation. With Kemper Development Company providing insights and input regarding their objectives for the project, MacDonald Miller and Trane worked through details and walked through potential issues to design a system that would meet the developer’s objectives.

Creating an optimal system design

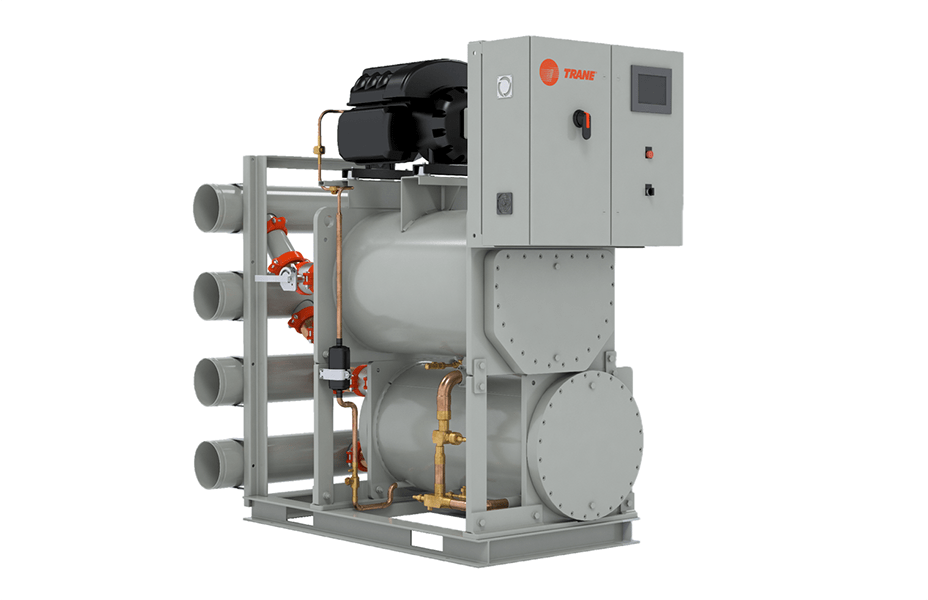

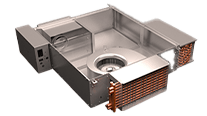

The team performed a life cycle cost analysis and extensive modeling of several chiller options to find the right solution for the project. Specifications for the project included a chiller plant with a 3,000-ton capacity and an expanded delta t. Four 750-ton Trane® CenTraVac® centrifugal water-cooled chillers were selected for the plant. CenTraVac chillers offer the industry’s highest full- and part-load efficiency in the industry and can operate with low global warming potential (GWP) refrigerants. The simple, robust, low-speed, direct-drive design of the chillers provides reliable performance, helps to reduce maintenance cost, and ensures quiet, vibration-free operation to maintain a pleasant living and working environment.

Providing comfort, reducing energy use

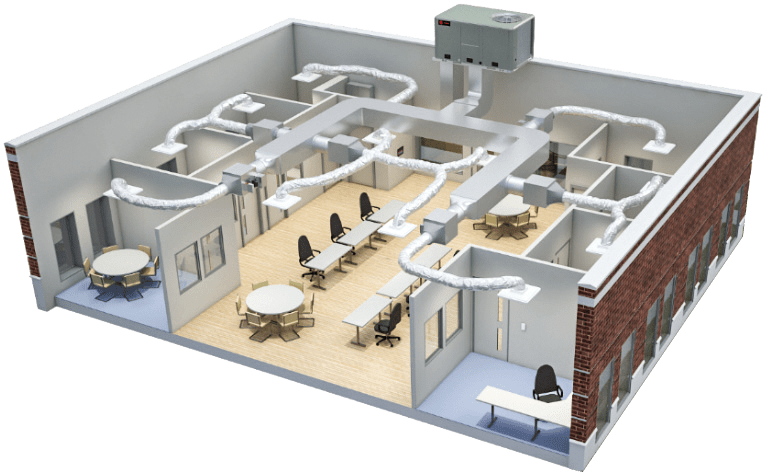

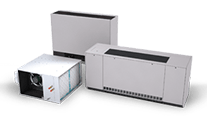

Operating at low sound levels, Trane® Performance Climate Changer® air handlers were installed in the south tower to efficiently deliver a clean, comfortable work environment for tenant offices. The variable-air-volume (VAV) air handling system with direct-drive plenum fans and electrically commutated motors (ECM) helps to reduce energy use and cost. Modulating the flow of air to meet demand requirements of the varied occupancy levels, the VAV system provides comfort for the tower’s diverse tenants.

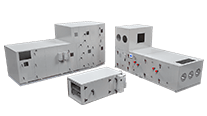

In the north tower, Trane vertical stack high rise fan coil units were installed to provide cooling, heating and high indoor air quality for hotel guests and high-end residences. The four-pipe units feature brushless EC motors for efficiency, noise abatement and motor-life extension.

Executing a team approach for optimal results

The Trane account manager met with MacDonald Miller engineers on a monthly basis throughout the project construction to review submittals, project schedules and construction details. Trane service technicians and service managers were brought into the meetings when additional technical input was needed.

The Trane factory-authorized service professionals also conduct quarterly evaluations to ensure that the systems are performing at their best. Addressing maintenance needs on systematic basis, rather than reacting to urgent service needs with costly emergency repairs, helps to reduce operating costs and eliminate unplanned downtime.

Results

Trane and MacDonald Miller Facility Solutions worked with Kemper Development Company to implement a new central plant design for the property owner’s Lincoln Square South complex. The central plant, which includes Trane CenTraVac® water-cooled centrifugal chillers, Performance Climate Changer® air handlers, and UniTrane® fan coil units, has improved the development’s energy efficiency, as well as the comfort of tenants and guests.

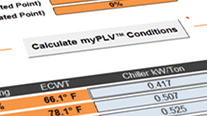

“The plant is operating at .49 kW/ton in part-load conditions,” said Dave Nieman, vice president operations, Kemper Development Company. “We’re very pleased with the performance.”

“Trane was a critical part of the team,” added Jon Sigmund, senior project executive, MacDonald Miller Facility Solutions. “From equipment delivery to start-up assistance to their service technicians. Everything from Trane was organized and on time as scheduled.”

ABOUT LINCOLN SQUARE EXPANSION

Owned by Kemper Development Company, Lincoln Square Expansion is a visionary 1.5 million square foot mixed-use development in the heart of Bellevue, Washington. The development combines fifteen restaurants, luxury apartments, the W Bellevue Hotel, six screen reserve-only cinemas, retail establishments and 710,000 sq ft of Class A office space.

LINCOLN SQUARE SOUTH

BELLEVUE, WASHINGTON

Project Highlights

Challenge

• Improve energy efficiency

• Remain budget responsible

• Address high humidity levels

Solution

• 3000-ton capacity central chiller plant

• Four 750-ton Trane® CenTraVac® centrifugal water-cooled chillers

• Trane® Performance Climate Changer® air-handlers

• Trane® UniTrane® fan coil units

Results

• Improved energy efficiency

• Improved comfort