Summary

ADTRAN, Inc. is a leading global provider of networking and communications equipment. ADTRAN’s products enable voice, data, video and Internet communications across a variety of network infrastructures. ADTRAN solutions are currently in use by service providers, private enterprises, government organizations and millions of individual users worldwide.

Challenge

When the controls system for ADTRAN’s East Tower was phased out by its manufacturer, the company sought to quickly resolve the obsolescence issue to minimize downtime. In alignment with its commitment to sustainability, ADTRAN specified a replacement controls system that would integrate with its current controls and allow connectivity between existing systems, while also reducing its energy consumption.

Solution

Impressed with the energy saving strategies proposed by Trane, and pleased with Trane’s previous work, competitive product offering and local service presence, ADTRAN selected the company to partner with them to find the best solutions to address their control system needs.

Controls upgrade and seamless integration

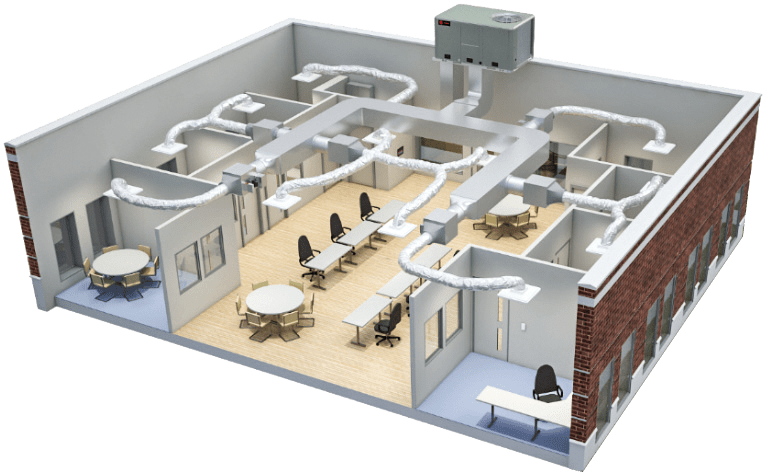

Controls on chillers, cooling towers, variable air volume (VAV) systems, fan coil and air handling units, head pressure valves, heat exchangers, pumps and refrigerant purge fans were upgraded. The programmable Tracer™ UC600 unit controllers and Tracer™ UC400 terminal unit controllers use a common, repeatable, consistent platform to provide greater flexibility, making them an ideal solution for ADTRAN’s special sequencing requirements.

The unit controllers are designed to work with the Tracer™ SC System Controller. With a complete portfolio of applications and an intuitive, easy-to-use interface, Tracer SC provides ADTRAN with a cost-effective solution for programming and managing facility climate. Accessible from any PC, tablet or connected device, facility managers use the controller’s webbased management tools for scheduling, reporting and applications programming to improve efficiencies, increase comfort and reduced energy costs. Tracer ES™ building management software enables ADTRAN to manage its multiple facilities as a single enterprise, integrating Trane controls seamlessly with ADTRAN’s existing equipment, controls and Tracer Summit® systems used in its other buildings via LonTalk™ and BACnet®.

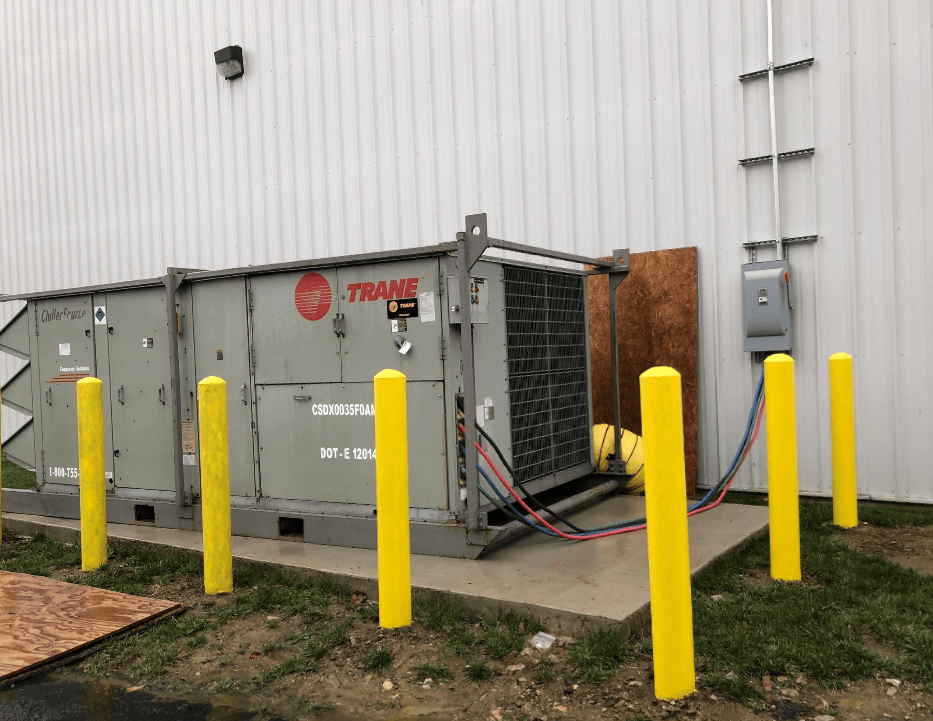

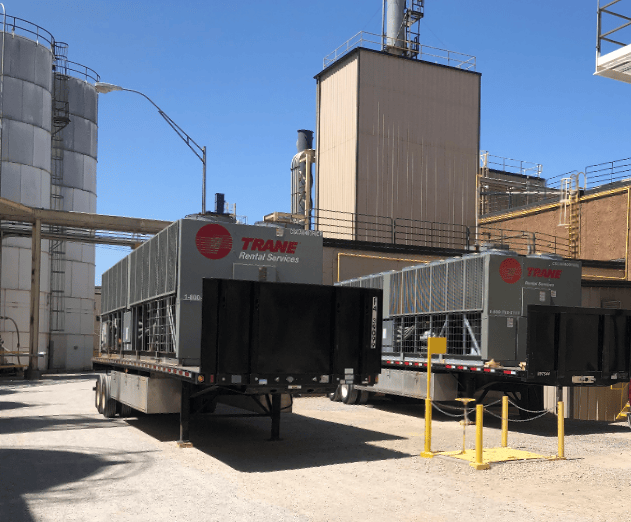

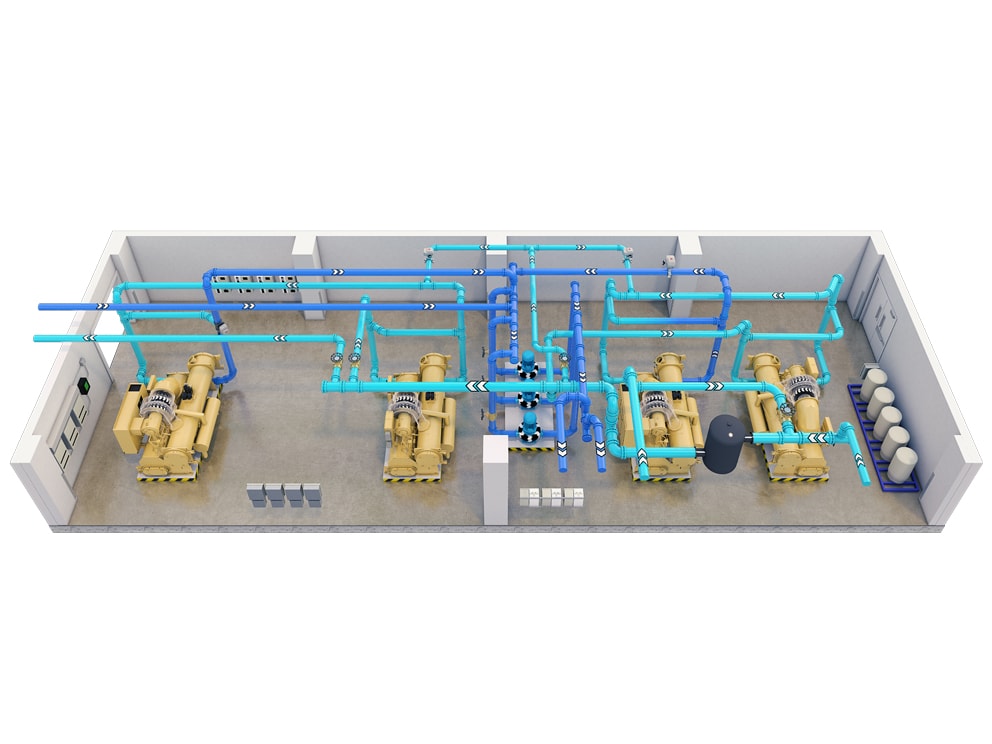

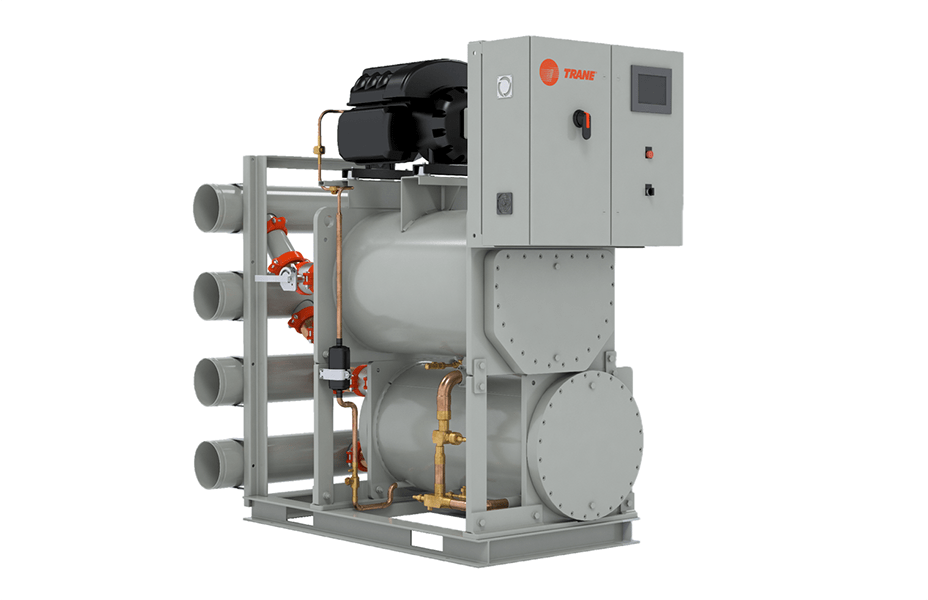

Out-of-the-box chiller plant control

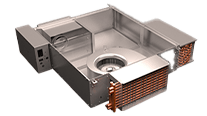

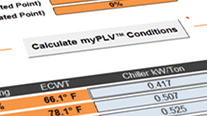

A chiller plant automation system and cooling tower sequence optimization provides the building operator with the tools necessary to balance the needs of building comfort/ process requirements and the desire to lower energy use, and operating and maintenance costs. System loads are monitored to determine the amount of chilled water needed, assuring that only the chillers required to maintain the load are operating. Condenser water temperatures are continuously checked to keep only the cooling tower fans that are needed to meet setpoint running. Using chiller/tower optimization the condenser water temperature setpoint is automatically reset to provide optimum system operation, minimizing the total energy consumption of the cooling tower fan and chiller combination. Chiller and cooling tower rotation, provided by automatic scheduling and operator request, allows the facilities manager to set up a method to equalize the runtime on all chillers and cooling towers.

Static pressure reset meets critical zone requirements

Static pressure reset automatically maintains the duct static pressure setpoint of a VAV system at the lowest possible level without sacrificing occupant comfort. The control system automatically identifies and maintains required airflow to the critical zones. Energy savings result from decreasing fan energy consumption.

Demand control ventilation reduces cost

Wall and duct carbon dioxide sensors were installed throughout the ADTRAN facility to help determine occupancy rates in the various zones of the building. A demand control ventilation strategy helps ADTRAN reduce operating costs by programming the system to respond to the actual need for ventilation in a zone by varying the rate at which outdoor air is delivered to that zone. Constant volume outdoor air and exhaust fans were converted to variable frequency drives, saving energy by varying fan flow rates according to occupancy or cooling loads.

Results

The replacement of the building controls system at the ADTRAN East Tower building has lowered energy costs, improved system reliability and now provides enhanced comfort for building occupants. The upgrade is projected to provide annual energy savings of 1.3 million kWh, even with additional power loads resulting from the relocation of a data center and fitness facility to the building, and the expansion of engineering labs. ADTRAN was awarded energy rebates of $133,680 from the Tennessee Valley Authority (TVA).

"The TVA requirements were very stringent and required detailed modeling to satisfy their rigid verification process," said Greg Smith, ADTRAN facilities manager. "Trane worked diligently with us and TVA to accomplish this unprecedented, complex project."

About ADTRAN, Inc.

Committed to sustainability, ADTRAN strives to reduce the consumption of natural resources throughout the company and the communities in which it operates.

Trane offers ADTRAN a local service presence and provides monthly Tracer Summit User Group training sessions for facility managers.