Lynnwood, Washington

Challenge

To efficiently and effectively address the needs of the community and avoid capital cost expenditures, the City of Lynnwood Wastewater Treatment Plant (WWTP) sought to address and prioritize items on its Capital Improvement Plan (CIP) and quantify operational savings opportunities. The City’s objectives were to reduce energy costs, maximize operational efficiencies, and reduce maintenance expenses by replacing equipment nearing end of life expectancy with more efficient equipment and improving processes. “Our existing centrifuges were old and needed to be replaced,” said Les Rubstello, operations and maintenance manager, City of Lynnwood. “We also were looking for ways to use less energy.”

Solution

Trane called on the City of Lynnwood and suggested conducting an energy audit to uncover energy savings opportunities. “We had already implemented several energy saving upgrades, and when Trane suggested doing an energy audit, we didn’t think we had anything left to find,” said Rubstello. “When one of our consultants suggested replacing our aging equipment with a screw press, we asked Trane to research the option. We also decided to go ahead with the audit.”

Streamlining the process

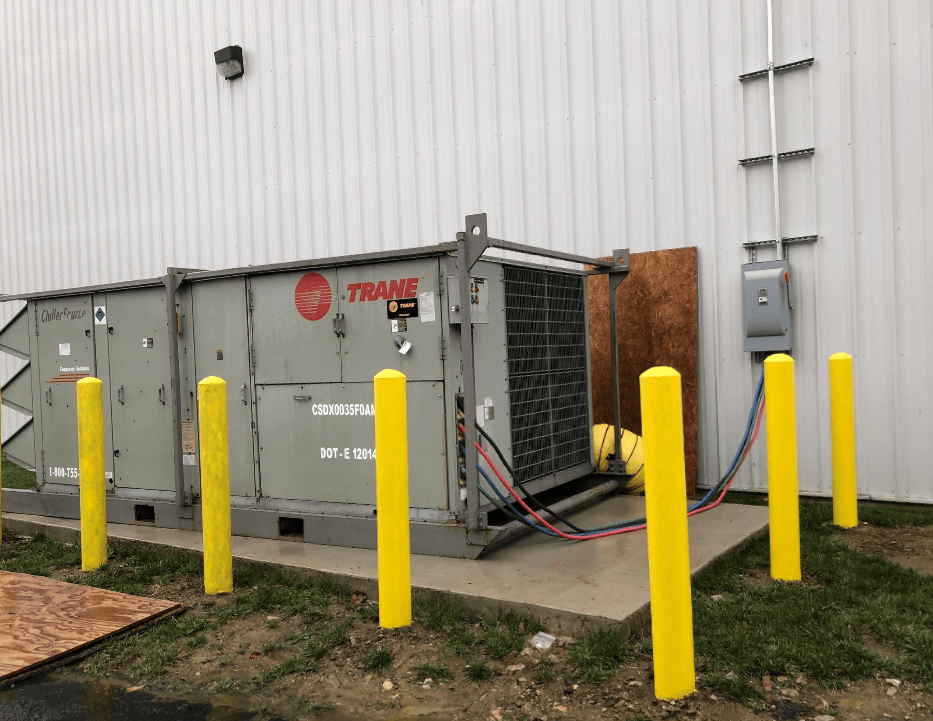

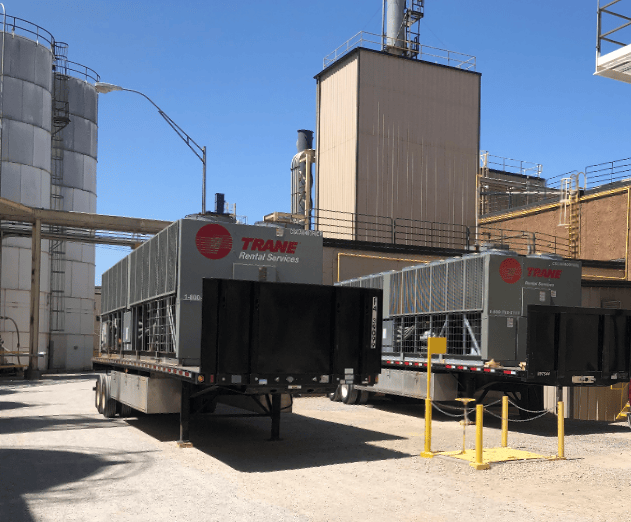

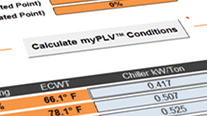

The City of Lynnwood selected Trane to complete an Investment Grade Audit (IGA) of their wastewater plant through the State of Washington Energy Savings Performance Contracting (ESPC) program administered by the Department of Enterprise Services. Trane identified a variety of energy conservation measures (ECMs) to improve plant processes and efficiency, which were prioritized based on audit results.

With Trane as their Energy Services Company (ESCO), the City moved forward to implement the suggested ECMs. The scope of the project included engineering design, construction, construction management, equipment installation, staff training, and measurement and verification (M&V).

“Using the state’s ESPC program streamlined the process,” said Rubstello. “Trane had already been approved by the state as an ESCO. They wrote the process, handled the day-to-day project management and had meetings or conference calls throughout the construction to let us know how everything was going. That made it a lot easier for us.”

Replacing aging equipment, maximizing energy efficiency

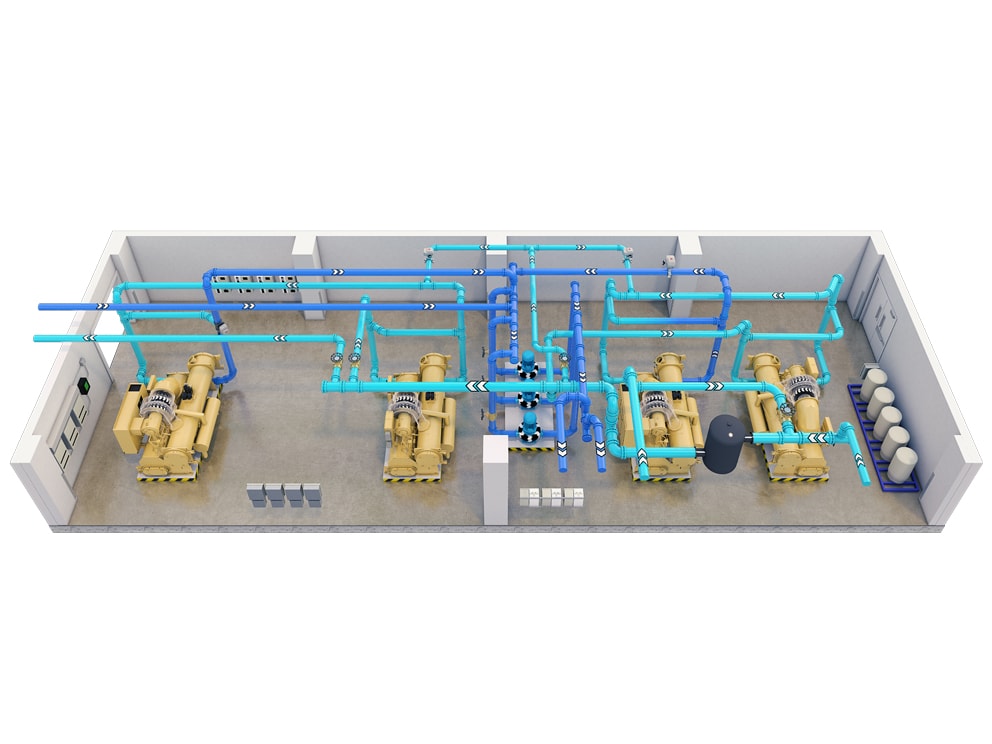

Two centrifuges were replaced with a single dewatering screw press and two new cake pumps were installed, allowing the plant to increase reliability and maximize energy efficiency, while maintaining a similar percent dryness dewatered cake product into the incinerator. To separate non-potable wash water into high and low pressure zones and reduce energy use, the two existing constant speed pumps, rated at 112 psi, were replaced with two variable speed pumps, rated at 40 psi, and a variable speed pump, rated at 80 psi.

“The screw press runs at a low rpm. It’s a simpler design and uses less energy,” said Rubstello. “Our old centrifuges were a nightmare to maintain. The screw press is a much nicer piece of equipment.”

Improving processes and operations

After the screw press installation, it was determined that the sludge thickener and degritter were unnecessary for the final bio-solids process. The equipment was demolished and piping revisions were implemented, creating more beneficial inlet sludge conditions for the screw press.

The existing sludge pumps and grinder, which were part of a process that was no longer needed, were removed. The change allows the primary clarifier effluent to feed directly to the sludge blending tank and creates a slight reduction in concentration to the screw press.

The heavy covers over the rectangular clarifiers were difficult to take off to ensure proper clarifier operation. As a result, the majority of the covers were permanently removed, causing the environment inside the building structure to deteriorate. New covers were installed that are easier for City staff to open. The new covers will help to improve operations, while also eliminating the need for the City to increase odor scrubbing capacity.

Results

Actively working towards leveraging resources and revenue streams to optimize operations, and minimize energy and operational costs, the City of Lynnwood entered into a State of Washington Energy Savings Performance Contract (ESPC) with Trane. As a result of the equipment and process upgrades, the City is reducing its energy usage by 247,116 kWh, for an annual utility cost savings of $15,850. Maintenance and operational costs have been reduced by $29,667 a year. In addition, the upgrades have qualified for energy conservation incentives from Snohomish PUD (SnoPUD) estimated at $53,132. The project is also helping the City to extend the life of critical systems, provide local green jobs for the community, and avoid planned capital replacement costs totaling more than $2.8 million over the next ten years.