City of Boise - City Hall West

Location: Chattanooga, Tennessee

Industry: Industrial

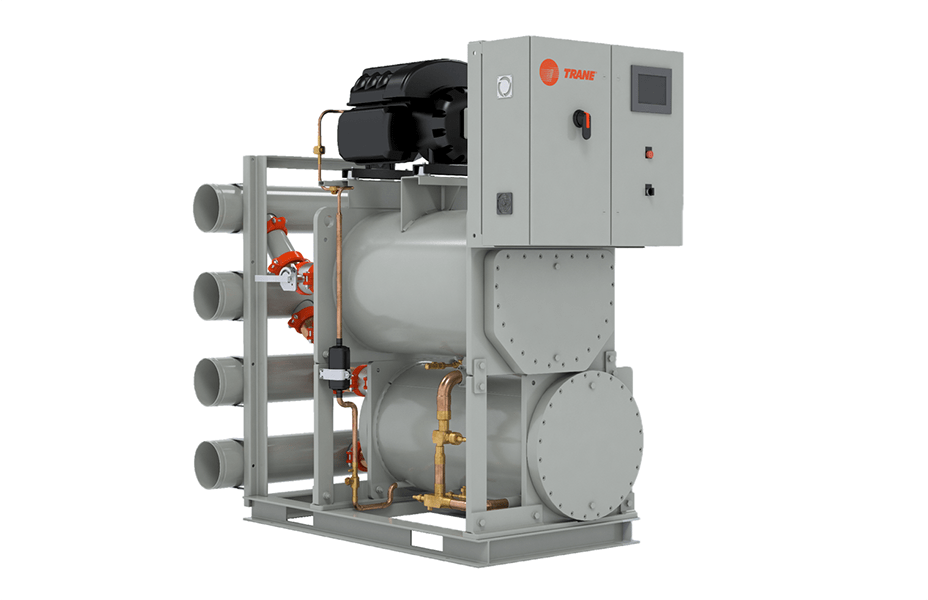

Products Used: Chillers, Controls

Services Used: Upgrading

Climate: Humid & Hot

Topic: Efficiency

Efficiency and reliability from Trane and Ingersoll Rand.

Efficiency, reliability and quality are among the hallmarks of Volkswagen automobiles. These same high performance characteristics are critical in Volkswagen’s manufacturing processes and can be found in the Trane air conditioning chillers and Ingersoll Rand Industrial Technologies air compressors installed at Volkswagen’s new assembly facility at Chattanooga, Tennessee.

Challenge

Volkswagen Group of America announced the construction of the new assembly plant at Chattanooga in 2008. The new factory will create an estimated 2,000 new jobs. Construction began in April, 2011. Initial production capacity will be about 150,000 mid-size sedans per year, designed specifically for the North American market.

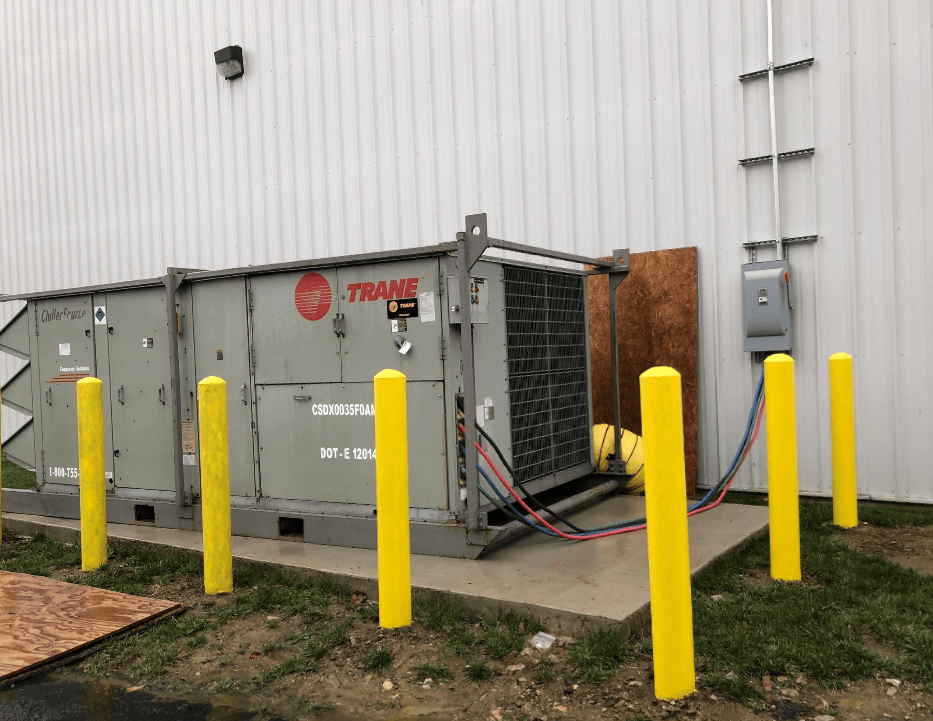

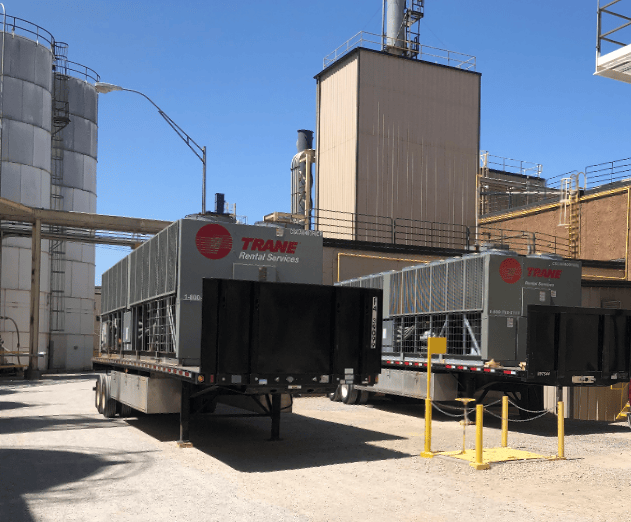

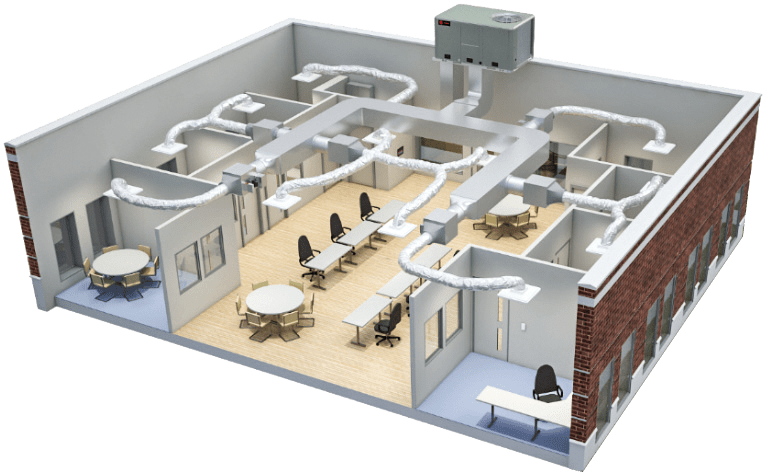

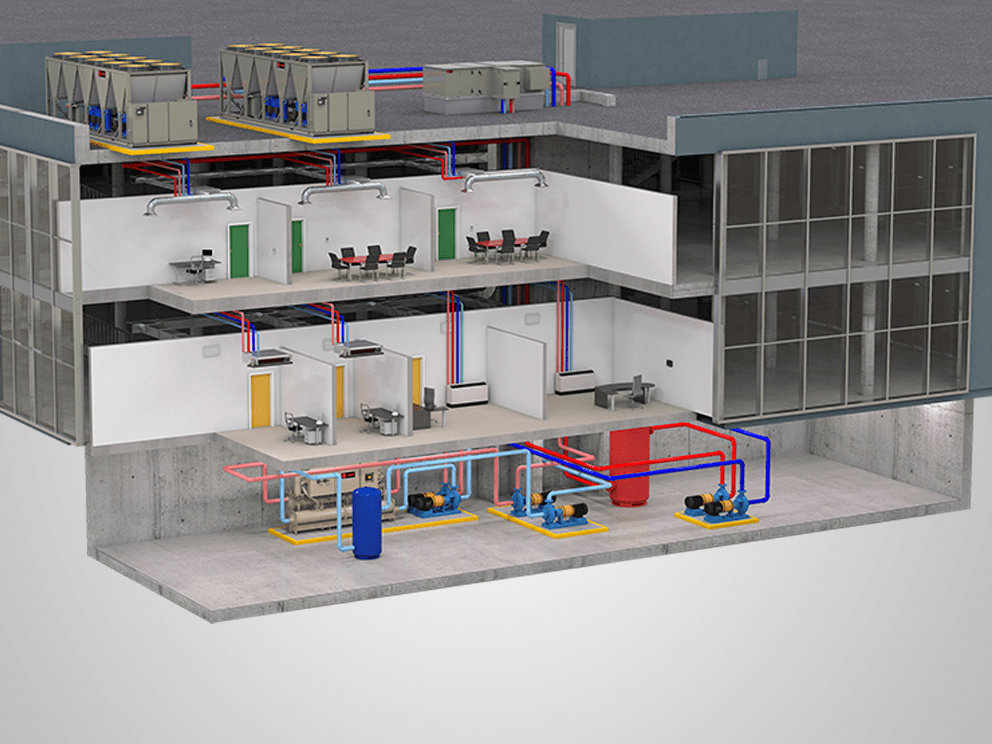

Among the systems needed for the new Volkswagen factory were chillers for cooling the plant and manufacturing processes including robotic welders and painting areas. Volkswagen also needed industrial air compressors to power the many pneumatic tools and processes. In selecting chillers and air compressors, Volkswagen required efficient, reliable performance plus on-time delivery to keep factory construction on schedule. Chillers and air compressors are mission critical. Without them the Volkswagen facility cannot operate. Efficient and reliable operation translates to lower production costs for Volkswagen.

Solution

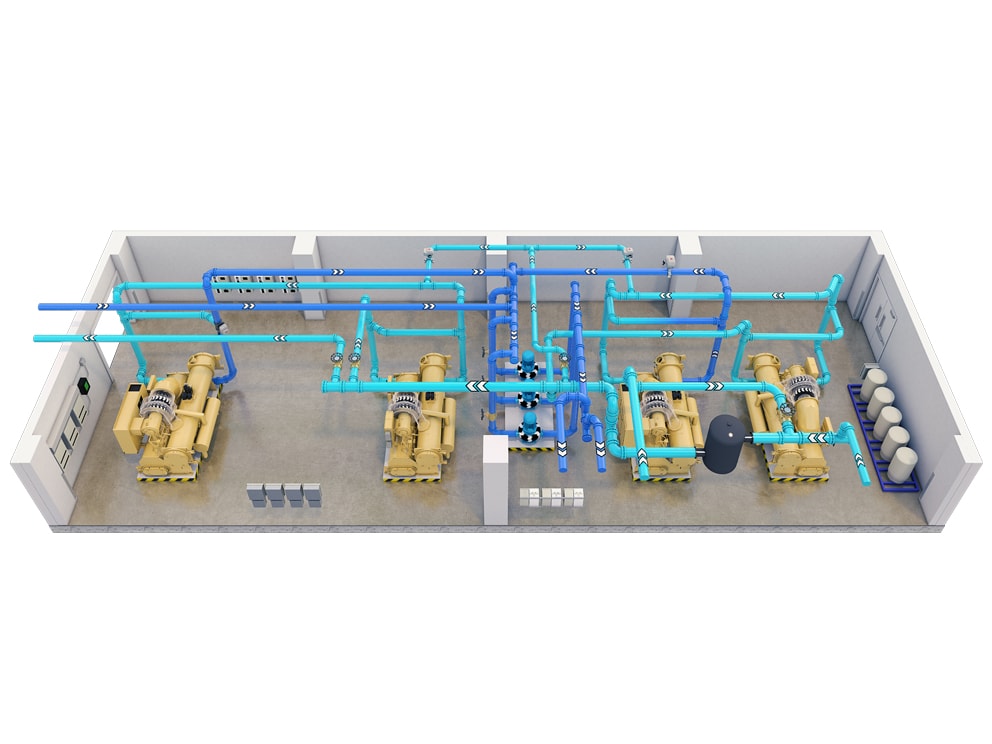

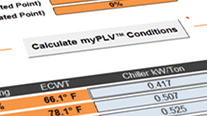

Volkswagen is investing more than $1 billion in the two million square-foot plant where they will build efficient mid-size sedans for the North American market. Volkswagen estimates that the new plant is 35 percent more efficient than other standard buildings, thanks to modern systems like those from Trane and Ingersoll Rand Industrial Technologies. Trane and Ingersoll Rand provided the systems expertise to make sure Volkswagen got the cooling and air compressor systems required. The chillers were run-tested at a variety of cooling load points on an ARI-certified test stand at the Trane factory, confirming the specified capacity and energy efficiency. Trane delivered the chillers on schedule and worked with contractors to help assure that all equipment was installed correctly. A Trane Tracer Summit™ chiller plant management system monitors and controls the chillers and interfaces with the overall facility control system. In addition to cooling manufacturing processes, the Trane chillers supply chilled water to Volkswagen’s IT computer servers.

Ingersoll Rand Industrial Technologies provided four centrifugal compressors and two oil-free, variable-speed rotary air compressors. The compressors provide compressed air for a variety of assembly and painting operations. The compressors are equipped with Ingersoll Rand energy-efficient dryers to make sure the compressed air is clean and dry. Chris Johnson, Volkswagen assistant manager of facilities-plant infrastructure, said, "Reliable compressed air is just as critical to our operations as chilled water and electricity. Without compressed air, manufacturing operations will stop in about a minute."

Trane and Ingersoll Rand Industrial Technologies are also providing services such as start-up and commissioning, parts and labor warranties, and periodic inspections.

Results

Trane and IR Industrial Technologies both met or exceeded the Volkswagen specifications for the chillers and compressors, and very importantly, met the delivery schedule requirements. Trane delivered the chillers in about half the time needed by other chiller suppliers. As a result of their performance in meeting Volkswagen’s needs, Trane and Ingersoll Rand Industrial Technologies have earned Volkswagen’s Preferred Partner status.

Chris Johnson said, "The chillers, air compressors and dryers,and chiller plant management system are all performing well. We’re very happy with the performance and we’re getting the support we need from Trane and Ingersoll Rand."

About Volkswagen Chattanooga

"The Chattanooga plant...will be the culmination of some of the best technologies and processes from Volkswagen plants around the world...the model for future plants." — Das Auto magazine