VO: You are listening to Cool Air Hot Takes.

Charles Jelen: Welcome to Cool Air Hot Takes. I'm Charlie Gellan.

Dan Gentry: And I'm Dan Gentry. Every couple of weeks we get together and bring you the latest in HVAC news. Of course, we do Hot Takes and we also have expert interviews with

Charles Jelen: industry leaders. And this week, special thanks to Andy Price and Jeremy Lee for helping us get this one set up.

We've got Mike Firo, he's the supply chain manager at Source Blue for Turner Construction. We're gonna talk about large scale supply chain management. It's everybody's favorite topic, supply chain. Uh, we're gonna talk about direct purchasing, how that's changed and what's changed in the space over the last two decades.

Later on, we're gonna talk HVAC headlines. We're gonna have another great installment of Dan Inside the factory, and then we'll close it out with stat of the day. Sounds like a great show, man. Season two finale. It is season two finale. You know, I listener out there, we do short seasons, we do six episode seasons, which I don't know if that's a marketing ploy or what that is, who knows?

But I do like having the season opener and season finale. It feels like we're, yeah, it's like an accomplishment. Exactly right. I, I totally agree. So is this a finale? This is a finale, season two finale. Alright, Daniel, I gotta ask you a question. Are you taking any supplements? Are you a supplement guy?

Dan Gentry: Uh, I don't take subs.

I'm just a natural. Everything you see here is what you get.

Charles Jelen: Just a little bit of old tosin every day and steak

Dan Gentry: and whiskey pretty much is

Charles Jelen: what fuels me. Okay, well, so I started taking creatine, which. When I was told I should start taking creatine by friends, I was like, well, I thought only high school wrestlers took

Dan Gentry: a creatine.

Yeah. I remember the creatine phase back in the day. Yeah. I, I think I probably like dabbled in some, but I didn't really get all in other Yeah, totally. I never hit the gym that hard, so I figured it's kind of one of those things you gotta do together. Yeah,

Charles Jelen: together. Well, it's not like I'm hitting the gym hard that much right now.

I mean, you look good. Oh, thank you. I appreciate that. But I, I did start taking creatine and I have noticed a difference. It's great. I love it. Really a little more energy. So my workouts are like road biking, mountain biking. Yeah. A little bit more, a little more energy in those. No, I like that.

Dan Gentry: I was thinking about getting on the whole, like testosterone.

I mean, I'm 41 little horse dewormer. Yeah. I don't know. Do I, do I need to do that? I, I haven't dove into that.

Charles Jelen: All right. Moving past the subs, but wanted to take a slight detour there. Yeah. Hot. Take time.

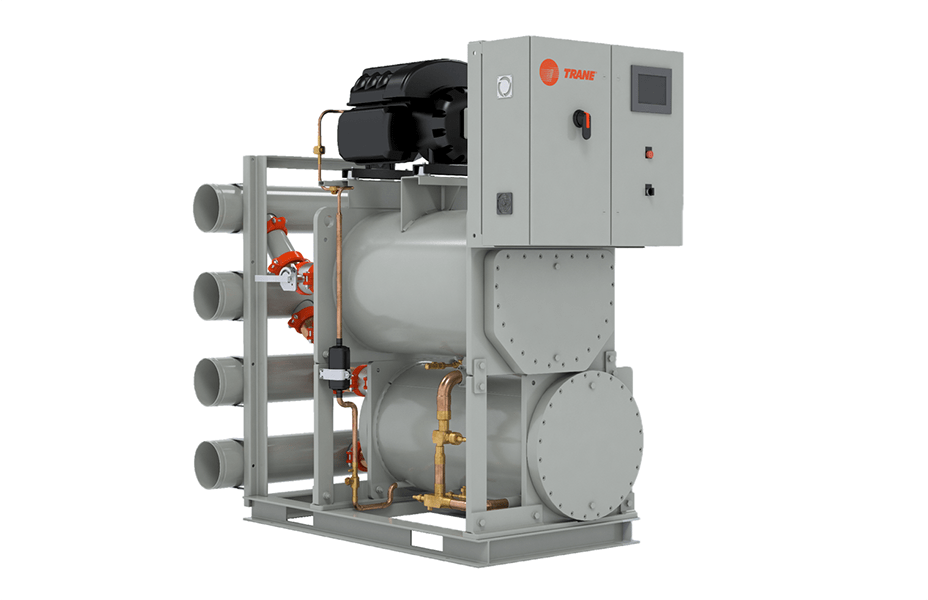

Dan Gentry: I can go. Okay. My hot take revolves around. Chillers with braised plate heat exchangers. So think like a lot of modular chillers, small chillers with scroll compressors.

The hot take is check the strainers in those bad boys, a lot of those chillers have onboard strainers. And a lot of times what we hear, you know, my design pressure drop is 10 feet. Why am I getting 25 feet across my chiller? What's going on? And the first thing I would say. Check those strainers. It's a pretty simple maintenance thing, but a lot of times people don't even know if they're there.

Yeah. So if you don't know they're not there, you gotta clean those bad boys. Love it.

Charles Jelen: It's a good one. Alright. What got mine is the originator of this one is actually Mick Schueler. Mm-hmm. He would say this all the time. A e DGS need to be used more often. What's a EDG? Advanced Energy Design Guide is what A EDG stands for.

They are absolutely free. They're put together by ashrae, so it's open source, but they are design guides for all sorts of different building types. Multifamily K 12, office buildings, grocery stores, hospitals, big box lodging warehouse, basically any kind of building that you wanna design. There's a.

Advanced energy design guide, and the way that they're set up is there's different levels. So you can pick a 30% A EDG, which means it's 30% better than code minimum. There's also a 50% better, and there's even a net zero design guide. Mm. These aren't like a, a paint by number. It's not like you, you use this thing and it's gonna tell you exactly what to do.

It is like a best practice for all parts of your building design. Use the stuff you like, don't use the stuff you don't, but at least it gets you set in the right direction and there's so much good information, especially if you're early career, check these out a G'S absolutely free.

Dan Gentry: No, that's really great.

And I, I would say I, me and even our group uses those all the time to reference people to like a, a common one that will get is what should my delta T be? You know it's not supposed to be 54. 44. Yeah. That's a random number.

Yep.

But what should it be? And I always refer to that guide 'cause they have different levels of guidance and their ranges.

Mm-hmm So it's like just gets you thinking about what's a good place to start.

Charles Jelen: Absolutely. Alright, good one. Remember we wanna hear your hot takes. We wanna get your questions. Let us know what you've got. You can send us an email, cool air.hot takes@train.com. You can leave us a review on Apple or leave us a comment on YouTube or Spotify.

You can also find all of the information from the show in the show notes. For every episode. Next,

Dan Gentry: we are gonna have your HVAC headlines,

VO: HVAC. Headlines your news today.

Charles Jelen: All right, listener, it's four 30 and Revic. Here's your headlines.

Dan Gentry: First headline is We are highlighting the 355th CES at the Davis Monmouth Air Force Base. I just thought this was kind of cool. It's mixing, uh, HVAC and the military together. I love it. So this is really, it's located in the heart of Tucson, Arizona and it's home to 11,000 airmen from 34 unique mission partners.

They support six combat commanders around the globe every day. Pretty cool. But, uh, really what they're tasked is like their job is to maintain the plant, keep everybody comfortable, and most recently was awarded the 2018 Commander in Chief's annual Award for installation Excellence as the best base in the Air Force.

Who doesn't like the military and HVAC mix together?

Charles Jelen: I wonder what it takes to be the best Air Force base in the world. I've

Dan Gentry: never heard of the commander in Chief's annual award for installation excellence, but it

Charles Jelen: sounds, well, it's clearly you need to have like top-notch HVAC. You need to have some good air conditioning, especially in Tucson would be my guess, but like good buffet, like good food, like what goes into that award.

That's a great question. Are veterans out there? If you're listening, let us know. Shoot us an email. Cool. air.hot takes@train.com if you have any idea here. But it was, it was cool. So the picture of this team here is in front of what looks to be a hanger. You'd find it in the show notes and it's, they're standing in front of the facility known as The Beast.

The Beast, which powers over a quarter of the air conditioning throughout the. Facility. What do you think the beast is? I did actually tried to Google search it here quick and they don't tell you what's on the base.

Dan Gentry: You could see some pipes. There's, I believe there's a chilled

Charles Jelen: water plant well do. Yeah.

Do you think it's water? Cool. Chillers and cooling towers? Think it's, I think it's cool. Ammonia

Dan Gentry: maybe. I think it's water cooled chillers with cooling towers. Just my guess, but I think centrifugal. Yeah,

Charles Jelen: I do too. I do. Yeah, these, these looks big. Yep. All right. It's a beast. All right. Good on you guys. Keep, uh, keep the Air Force cold over there.

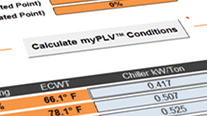

Thank you for your service guys. Absolutely. Thank you for your service. Headline number two, the headline reads what comes after R 4 54 B and R 32. Oh, so this is from A CHR news, but this comes up all the time. Mm-hmm. Is R 4 54 B and R 32 replaced. R four 10 A, R four 10 A had a GWP 20, 1400,

Dan Gentry: 2000, something like that.

Yeah,

Charles Jelen: yeah, yeah. And we needed to get down to like 700, 7 50 and, and so. 4 54 BR 32. Those were the replacements that we're using. And, and the, the equipment that we're primarily talking about is unitary equipment, rooftops, water source, heat pumps, things like that. Small stuff. Scroll compressors. Yeah.

Primarily small, under, under 200 tons. Typically, the other side of the commercial equipment. Bigger stuff. Air cooled chillers, water cooled chillers. We're using gwp that are much lower and we have options that are under tens. Call 'em ultra-low GWP, and so the general industry consensus is at some point in time it looks like we're going to have to take another step down in GWP for these high pressure refrigerants that we use in the unitary space.

I'm not sure that's actually gonna be required in the short run.

Dan Gentry: Okay.

Charles Jelen: With this current administration where the EPA sits right now, they're not pushing, they're actually looking to pull back some of the AIM rule. So I don't know if this is gonna happen in the short run, but maybe long term, if we did have to go to lower GW p refrigerants, that's what this article gets at is like what?

What would the options be? And long story short, there's not a lot of great options. I was gonna ask,

Dan Gentry: what do they even pose Any like viable.

Charles Jelen: Well, there's, so like if you go to Europe, they're using propane. Propane's got a really low GWP, ultra low GW P, and it's really efficient as a refrigerant, but flammable, very flammable.

Not even a two, it's a three category on the flammability chart. It'd be a big change and it's nothing that we couldn't work through. Like obviously if you think about like how you heat your home or how you heat most businesses, you've got natural gas piped into your building. Yeah. And that is very flammable as well.

So there's clearly ways that we can get around it. This is a different ball game, but we could work through it. I don't think it's gonna happen in any short amount of time here. Mm-hmm. Um, but that's what they're getting at is like what's next on the horizon. And it's, this has been a rough transition from four 10 A, especially for split systems.

Like how do you replace the outdoor condensing unit with the indoor coil de have to replace whole thing and then ul and. The best. This has been a little bit of end like there's been some supply chain issues, so I don't think anybody's really excited about moving to another refrigerant right now. I think we got lots to play out a little bit, but yeah,

Dan Gentry: we'll see what

Charles Jelen: happens.

All right. Up next we got Mike Fierro, supply chain manager at Source Blue for Turner Construction. Don't go anywhere.

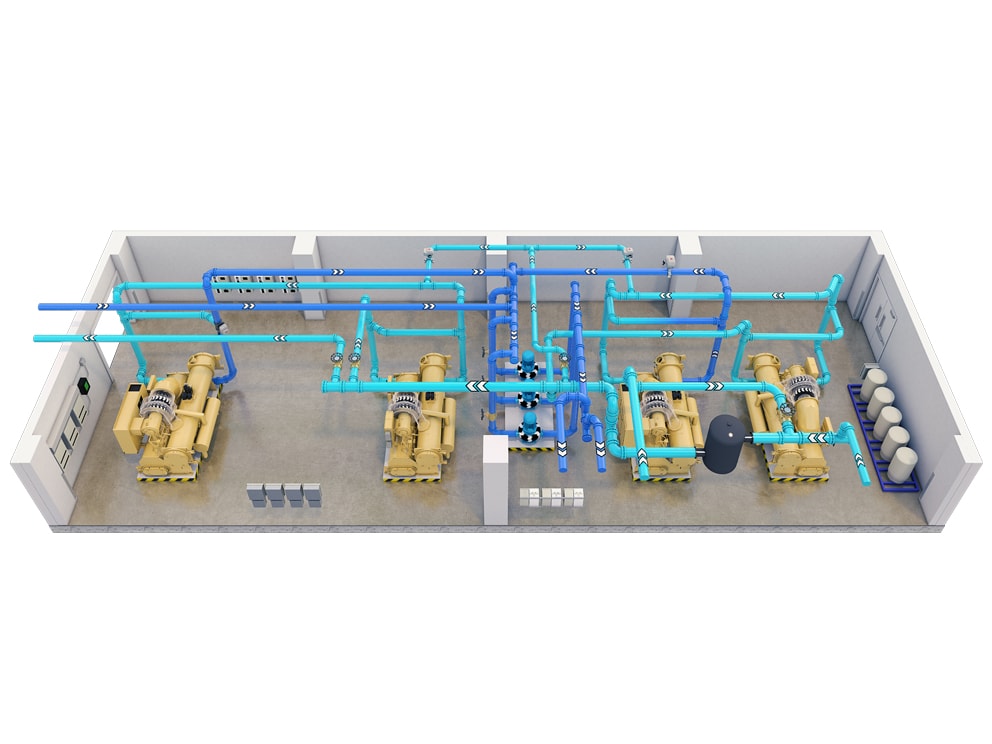

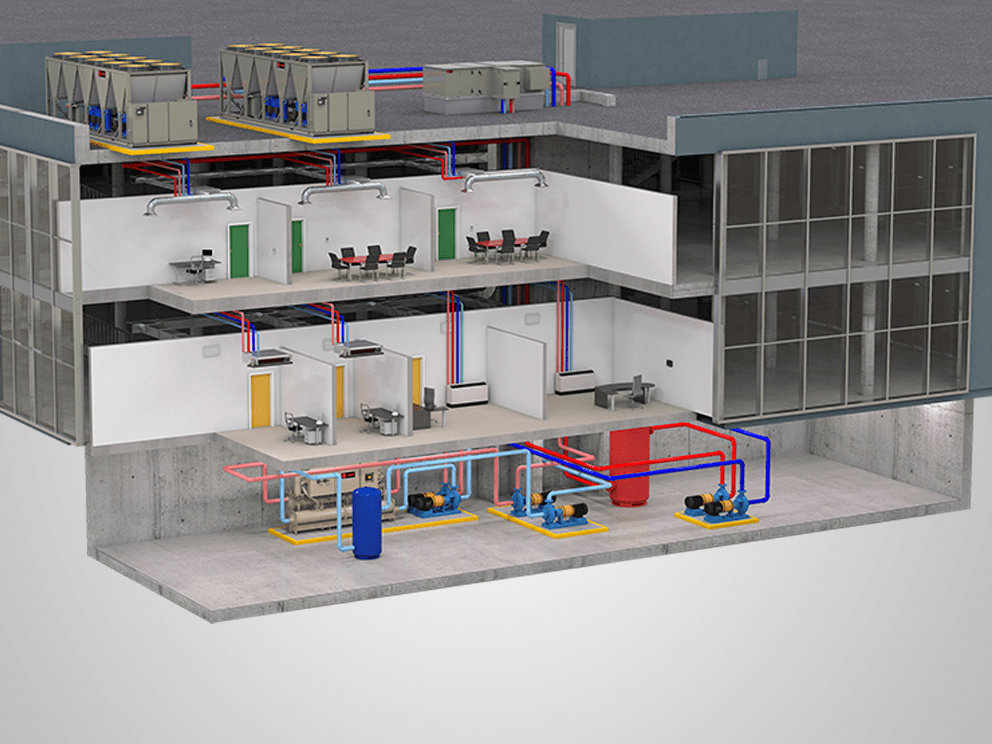

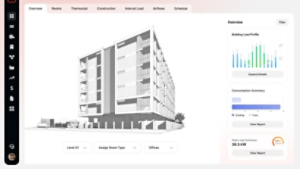

For all your listeners out there working in the data center space, listen up. Trane has a dedicated team of specialists here to support your efforts. Need help with detailed chiller layouts, bingo, complete hydronic and energy distribution design, including CDUs, crawls, and fan coil walls. Bingo.

Constructing a microgrid to provide your own power. Bingo. That's right. Trane has the resources to back you up. Reach out to us@coolair.hot takes@trane.com or connect directly with me, Charlie Gellan on LinkedIn to learn how we can help support your next project. Bingo. And now back to the show.

All right, listener. Today we have a friend of the show who does not need an introduction because he's not afraid of talking. All right, so today we have Mike Fierro. He's the supply chain manager at Source Blue for Turner Construction. Mike, welcome to Cool Air Hot Takes. How you doing today?

Mike Fierro: I'm doing great.

Thank you for having me.

Charles Jelen: Where are you at? Where are you located? Where are you from background? Give us a little bit, uh, of who Mike Fierro is.

Mike Fierro: Sure. So I'm located in New York. I'm actually in Rockland County.

Charles Jelen: How far away are you from like your home? Home? Three miles.

Dan Gentry: Nice. Nice. We have that like in common.

Yes. This is good. I was born and raised in lacrosse and I live right down the road from where I was. All

Charles Jelen: three of us are within three miles of our like original home. Yeah, that's pretty cool. Alright, so grew up there, raised there. How'd you get into construction? That's family

Mike Fierro: thing. My dad was in construction.

My sister works for Turner Construction as well. I got a few cousins. My father-in-law and my brother-in-law are both in the industry. I was a mechanical engineer at school by trade, but I was in automotive and they didn't pay much, so I moved over to construction. They paid a lot more up front, so, and that's how I was interning.

That's how I got my job. I basically never had. A job interview in my life if, if you could believe that.

Charles Jelen: How nice. And you've been, just went, went up through the ranks, jumping, went right through it. Yeah. Yeah. That's great. That was awesome.

Mike Fierro: People like, what should I do for a job interview? I'm like, I don't know.

Never did it before. So I, I tell you,

Charles Jelen: that was pretty good. All right. Uh, so job interview question. If you had to be. No, I'm just kidding. So you've been at Turner Construction how long? Almost 25 years. Since 2000. 25 years. Nice. Alright, well the name of the show is Cool Air Hot Takes. And so every guest we have on, we have 'em bring a hot take with them.

Could be from your personal life, professional life, anything in between. Did you bring a hot take today?

Mike Fierro: Yeah, we did.

Charles Jelen: What do you got?

Mike Fierro: So I wanted to talk just on what I was dealing with this sustainability and electrification. Right. And what I wanna touch on is how. I think in the US we didn't do a great job of it because we tried to do it too quickly.

Right. And I think it's something we have to do, and I think Trane was one of the first people with the heat pump technology and the new refrigerants and all these things. They're great.

Dan Gentry: Mm-hmm.

Mike Fierro: However, we were trying to run so fast what you should do in order to get people to innovate that we didn't do the transition well enough.

And now I feel that because we ran so fast and so hard and some people didn't like that, we're taking a step back that we shouldn't be if we were able to transition it better.

Dan Gentry: You know. All right. I like that. Can you dig in a little more, like, did like a problem manifest? Like were projects difficult to get off of or get going and Yeah.

Going operation, like were they complex or what kind of, uh, hurdles were there?

Mike Fierro: So I think the biggest problem that they had was people try to do, say a job in, I don't know, Canada with heat pumps.

Charles Jelen: Mm-hmm.

Mike Fierro: And for lack of a better word, especially when the technology first came out, it was just too cold and they couldn't do it either.

They needed some like ridiculous arrays or they didn't have enough power, which Canada usually doesn't, but like other places in the US the grid wasn't strong enough. It wasn't reliable enough where with the natural gas and stuff, it still could do it. Mm-hmm. And a lot of the design was difficult 'cause they were trying to do this thing and get everything.

Heat pump, everything electrified, switch gears were so much bigger and they just didn't quite understand it. And I think really the grid was the hardest part that you don't have that infrastructure. To support the electrification even on just like the grid itself with renewables and whatnot, so many renewables.

But then because, so variable storage wasn't really there. The technology wasn't the best and they had to waste a lot of things. So I think that transition just went a little too fast and we're kind of backtracking. So hopefully we can get back on track. And I see it a lot with the heat pump jobs. We're getting way better now.

And yeah, the hydronic side is better, but it was just, we went too fast.

Charles Jelen: Yeah, it's an interesting take. I feel like you hear more people say that we're not moving fast enough. Yes. And they look to Europe and they're like, yeah, look at what they're doing. And all these things. And there's a million different variables that go into why and how and and all that good stuff.

But to say that we went too fast or tried to follow that too fast, it an interesting take. Mm-hmm. And that leads us in, let's start with where you're at now. Alright. So you are. Managing a supply chain for a, a massive company. All right. Give us an idea. What is this role that you have about what are the main things that as a supply chain manager for Source Blue, what are you doing?

Mike Fierro: So, I'm the product manager. So I support regional people across all of North America globally as well to assist them in either suggesting certain vendors that we deal with. 'cause my team also travels out to all the factories. We see it. We understand the capabilities of them. So if someone says, Hey, I have a hospital in Michigan and it's a $30 million air airline job custom with these types of options, the spec says X.

We have all these people. Who do you also recommend? What are the pros and cons? Who are your contacts there? Right? 'cause we have contacts direct at the factories. So since we get that, we can, for lack of a better word, kind of cut through the BS of some things that might happen. And understand if someone's giving us a yes, yes, yes.

Or someone's telling us the truth so we can give our people better information and give the clients a more informed decision on whoever they're picking in the equipment. Hmm.

Charles Jelen: I've gotta imagine as a supply chain manager that your level of, uh, interest. Has changed in the last five years. Yeah. Uh, like pre COVID first, after COVID, I feel, I mean, how do you feel about

Dan Gentry: lead times?

Charles Jelen: Like before COVID supply chain? I don't even know if like, maybe I heard that word once a year. Totally. And now I hear it every day. Yeah. So what happened in COVID and how does that change your role?

Mike Fierro: Well, I mean, COVID for me as the supply chain manager, I'll call it the fire drill guy, right? So putting out fires, yeah, was terrible, right?

It was every day lead time stuff is late. What do we do? How do we do it? But it also was very helpful to Charlie's point before. COVID like supply chain. What's that?

Dan Gentry: Yeah.

Mike Fierro: After COVID, everybody's, oh my God, you work in supply chain, what do you do? And then all of a sudden people wanna talk to you, right? So it was one of the best sales pitches we ever had.

And our revenue growth totally backs that up. You know, in 22, 23, we went up four and five X. 'cause at that point, people understood the value of knowing your supply chain.

Charles Jelen: Damn.

Mike Fierro: So it was phenomenal for us. So we had jobs and a lot of the jobs were, Hey, what equipment do I order so I could meet my schedule?

Right? Yeah. Especially to say ECM fans. Right. Oh my God. ECM fans 90, a hundred weeks. So let's go back to AC motors and BFDs and we can do this, but if we get this one, if you have different sizes, these are only like 40 weeks. Right? So there was, we were able to get in a lot more on the early side work with the engineers and help them, right.

And say, here's your design. Great. But if we change this and this, your lead time will go from 80 weeks to 30 still. Yep. Major design intent. But because we know you can't get this go with here, this vendor's doing better. Right. There were certain vendors that built up inventory before COVID. Mm-hmm. And they destroyed everybody else.

If they didn't do that buildup, it was done.

Charles Jelen: Yeah. Yeah. It, so pre-purchasing is a huge thing in our industry now, especially. Yeah. The data center side, how long has that been going on?

Mike Fierro: I think it's been going on for years. Right. We've been doing it for 22 years.

Charles Jelen: What were historically like the projects that you guys were doing that for?

So again, and what were the products that you were doing?

Mike Fierro: Okay, so projects, right? In 2001 when we started was the data center. At that point it was when the cloud started to get built out. Yeah. Right? Yep. And then the Microsofts and the Hyperscalers and all those guys were like, Hey, we can't get generators.

We can't get. Switch gears. You know, at that time it was like 30 weeks was the end of the world. Right. So I, they didn't understand where it could possibly go. Is would love 30 weeks right now.

Dan Gentry: Yeah.

Mike Fierro: Wow. Right. So Turner Construction's like, how do we get a hold of this? Like this is a huge problem.

Dan Gentry: Mm-hmm.

Mike Fierro: And then they grant people from the industry brought 'em in, said, Hey, like what are the turns we need and how do we set this up so that we can get preferential slots? And scheduling. And pricing.

Dan Gentry: Yeah. And

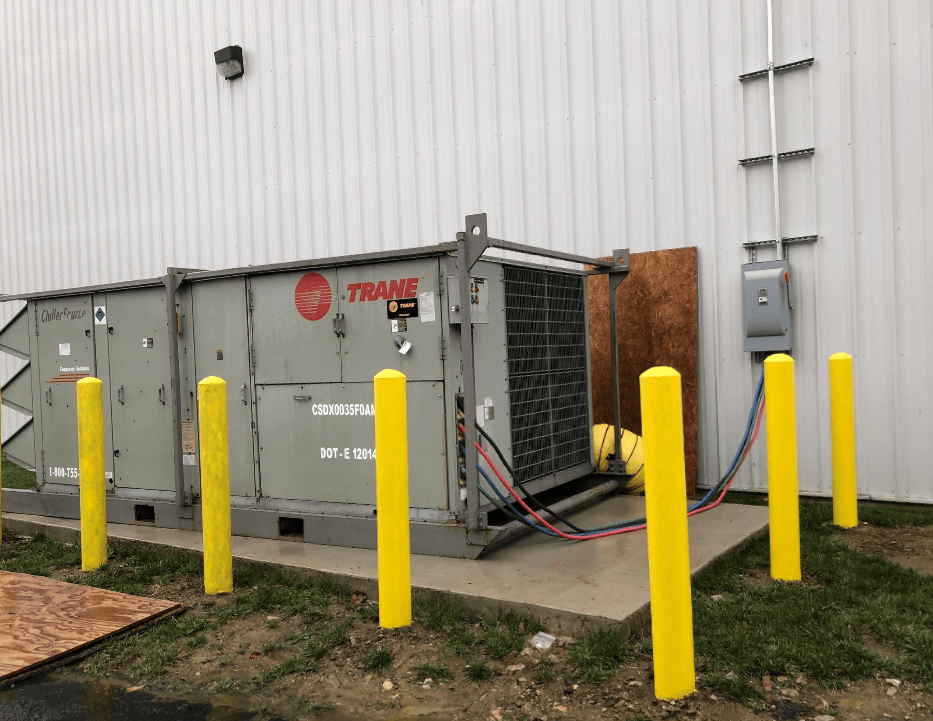

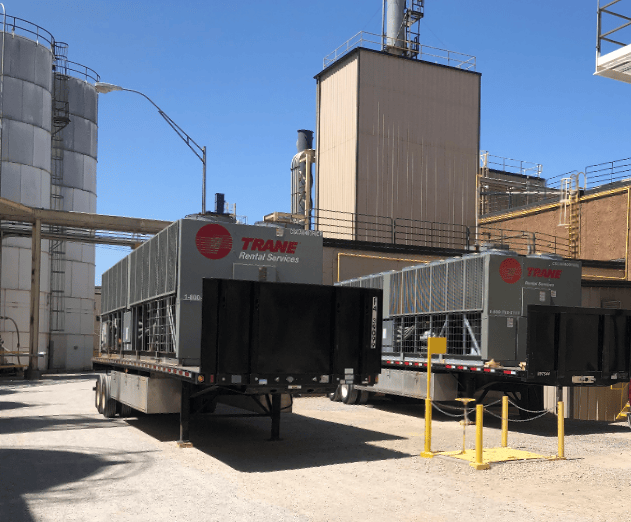

Mike Fierro: internal logistics, which is what Source Pool used to be known as. Was born out of that. So again, the big products that we deal with on the mechanical side is chillers.

That's number one. Uh, on the electrical side it was generators and switch gear and Okay. Some high voltage transformers. Those are the big lead time stuff in the data center world.

Charles Jelen: So that's historically been the case. Where those are the items that you're pre-purchasing through COVID and now ai boom. Is it all still the same stuff or like what drives those decisions?

Mike Fierro: Most of the time it's lead time. Okay. Right, because we can be involved before a contractor's on board or any of that stuff. And also you don't even need your full design, right? Yep. You don't have to have your distribution stuff done. And we could order a chiller. You get order air handlers.

Charles Jelen: Okay. I I do have to ask, sorry to interrupt you, but like, that sounds risky, right?

Because it's true. A lot of the units that we design are customizable. There's a billion different iterations that we can do on any given chiller. At what point does the design has to progress to some level?

Dan Gentry: Yes.

Charles Jelen: Where it's like, alright, we'll buy that now. Then the design progresses and then you just hope at the end that it matches up.

Like how do you guys manage that risk?

Mike Fierro: There's a point where you have to

Charles Jelen: be

Mike Fierro: assertive, right? So let's go to a real big job. We do design assist. We have a chiller. We know approximately how many tons, but say the air handlers change slightly, coils change slightly. As we're moving along, if we have to make a design change or take one chiller out, edit, we can do that things and do it.

But there will be a pointment saying, Hey, listen, I need to be. Done. Now the factory has to be finished. They have to finish their engineering if we're gonna hit the date.

Charles Jelen: That seems like such a tough one because the systems that are ultimately serving, a lot of these big projects are all bespoke. Mm-hmm.

If you were still doing it plan and spec and not pre-purchasing anything, how much extra time would your typical data center take today?

Mike Fierro: Oh my months, especially on the electrical side. For transformers and generators, sometimes chillers, right? Sometimes your chillers can be 50 to 70 weeks, right? They're

Dan Gentry: Well, and it can be an issue too, you think with any factory, when you're gonna put in an order that is so large, you know, you've get those spots and if you wanna make a change, it may not be as easy as just moving that slot up or down a little bit.

It could be big

Mike Fierro: and probably phasing out the job too, right? 'cause if we have a couple of jobs that are about 150 chillers a piece. You're not getting 150 chillers at one time, right? You're getting two a week or something like that. It's gotta be phased out.

Charles Jelen: What general product category has the longest lead times?

Mike Fierro: Uh, I would say generators or high voltage transformers. It again, on the mechanical side, chillers without a doubt it's the biggest expense. 'cause we have like the fan walls or data center CDUs. Mm-hmm. Yep. Even those, they're not to 25 weeks, 30 weeks, something like that. Again, for the first one to do it.

Dan Gentry: Mm-hmm.

Mike Fierro: But yeah, I think generators now selling 'em are still like 150 weeks.

Dan Gentry: Geez. Really? Wow. A hundred. I hadn't heard that.

Mike Fierro: Yeah. For a specific size that someone gets it. Yeah. 'cause again, with these data centers, you could have one client send one of our vendors. A billion dollar PO for equipment with a B.

That was with a B, not with an M.

Dan Gentry: I always hear that about switch gear and I always, like, Eaton is down, whatever, east of us on the interstate, and I see those green boxes rolling down the interstate and I'm always thinking, man, somebody's gotta be so happy to be getting that gear. And I really hope that truck doesn't, uh.

You don't have an accident or something. Yeah,

Mike Fierro: that happens too.

Charles Jelen: Yeah. What, what advice would you give people around that, right? Like you're coming from the supply chain from like a really big company and you're a big buyer and you're working on big projects. If you had one piece of advice to give to the people designing those projects from a supply chain lens, what would you tell them as they sit down to start?

Mike Fierro: Ooh. I think the biggest thing do one

Charles Jelen: thing

Mike Fierro: is you have to make sure we get all of the people in the room, right? Let's stick with data centers. Make sure you have the IT guys in there, the procurement guy, like all the stakeholders. They have to be together. If they're not, and there's some silos that happen.

Then things won't happen properly. Or someone's like, Hey, I'm a facilities guy. No one asks me a question, like, I don't want to use this person, or I don't like these motors. Right? Get everyone into the room. Expectations are set and you'll be able to design better and have your job run smoother, more efficiently.

Source blues in the room. Does that ever happen? It does. I think now we're, we work with some yeah. Of the hyperscalers directly. And some of them have us on some of the fastest moving jobs you could imagine. We built a job with one of the hyperscalers. It was a 36 megawatt low density facility. Mm-hmm. We built from dirt on the ground to operating data center.

In two and a half months. Yes. I said two and a half months. How many

Dan Gentry: serious procurement happened in, uh, on, and there

Charles Jelen: were, how many parts did you steal from other jobs? Be honest,

Mike Fierro: the client did. The client did, and we helped 'em out with that. But on that one, we had train air handlers that were the fan wall units.

We got the request on Wednesday. We spoke with Trane on Thursday. We issued the PO on Friday and there were units on the floor on Saturday morning at Fort Smith. That is not a joke.

Charles Jelen: You do know your factories. You do know your factories, don't you? Yeah. Oh yes. That's impressive.

Mike Fierro: And I was there. I was there Tuesday after that I was at Fort Smith and like 16 units were already built, so in less than a week we went from order design submittal units on the floor.

16 units built in like five days.

Dan Gentry: Good job Fort Smith. Huh?

Charles Jelen: You know, I didn't know you'd, you'd help us out so much on the marketing side here today, but I am. I don't mind it. I appreciate it. All right, Mike, thanks so much for coming on. That was awesome. It was a good conversation. Learned a lot about supply chain.

Mike Fierro: Mm-hmm. Yeah. Well, thank you guys for having me. This was awesome. Thank you.

Dan Gentry: Hey Charlie. Hey buddy. Uh, did you catch train's latest webinar on

Charles Jelen: VRF systems? Dunno why your voice is going so high, but no, I haven't. What's it about?

Dan Gentry: Well, it's actually about understanding the impact of a 12 refrigerants on VRF system design and installation.

Charles Jelen: Oh, yeah. Lots to unpack on that one.

Absolutely

Dan Gentry: lots to consider

Charles Jelen: on how VRF systems are designed with next generation refrigerants, death, taxes, and refrigerant transition. Sounds like a must watch for any engineer. Where can our listeners find this, Jim?

Dan Gentry: Oh, you bet. Just go to trane.com/vrf or click on the link listed in our podcast episode below.

How about we. Back to the show.

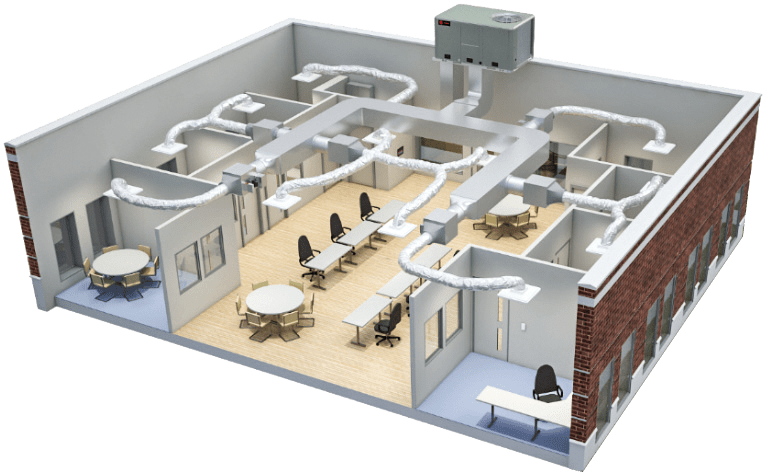

Okay, let's know, this week we are going back in the factory. This has been an organic segment, if you will.

Charles Jelen: Grassroots, grassroots,

Dan Gentry: grassroots. We had some grassroots engagement on this. So this week we are actually gonna go into one of our testing labs where we test chillers and it's gonna be really cool.

So let's go to the lab. All right, listener. I am in our lab in La Cross Wisconsin, and I have a guest today, Mr. Mooney, with do you wanna introduce yourself and tell us a little bit about yourself?

John Mooney: Uh, yeah. My name is John Mooney. I've worked at Trane for a little over eight years. I got around two years of experience working in the factory, doing like brazing and assembly.

Got my associate degree in hvac and then uh, I managed to get an internship in the lab, so I had to leave the factory and come over here.

Dan Gentry: It seems like a really cool place. You guys have like a ton of. Technology and like tons of different stuff.

John Mooney: Yeah. There's uh, there's a lot of new products and you get to hear about what's happening throughout the company.

A lot over here. 'cause everything that the field returns that are more difficult to fix, to get sent over here.

Dan Gentry: You guys get to fix it all.

John Mooney: Yeah. Yeah.

Dan Gentry: Cool. Well, let's go walk on the floor and look at a couple things and see what we can find.

All right, we're standing in like the middle bay area. I think I see like, I don't know, 20 different chillers set up here. A very compressor technologies. I see modular package screws, centrifugal scroll. It looks like this is some kind of a test unit. I probably can't ask too many questions about this one.

It kind of looks like a Frankenstein and it's got a code name, but it looks like, you know it's got scroll compressors. Several braise plate heat exchangers. We're gonna put something neat together here.

John Mooney: Yeah. So it's just gonna be heating only.

Dan Gentry: Okay. For

John Mooney: that.

Dan Gentry: Okay. Very cool. And then behind us, we got a whole.

Array of large centrifugal chillers. So different refrigerant testing, different performance longevity.

John Mooney: Yep. So this one here, they're working on field failures.

Dan Gentry: They're surprisingly, probably sounds loud on the audio, but for the size of this machine, it's not very loud. I mean, that's a big machine. That's a lot of capacity.

A thousand tons or so, and it's not too bad.

John Mooney: Yeah, I think that's a 1300 tons chiller. Okay. Very loud, or it can go pretty quiet.

Dan Gentry: I love it.

Charles Jelen: Alright, Danny. Boy, that was good. A little, uh, peek behind the curtain in the lab there. What, uh, did they have anything else you're gonna, uh, bring? Dan inside the factory too. That was in the lab.

Dan Gentry: Are you alluding to another, another segment? I think we're gonna keep it going. I, I think our guests may just have to stay tuned.

Alright. I think it's a good idea.

Charles Jelen: Yeah. Listener. If you've got ideas or if you've got suggestions on other things that you'd like to hear about inside the factory, inside the lab, inside our offices, just let us know. Cool Air hot takes@trane.com. Up next Sta of the day. Here come Joe Sta. The day, the day.

Day of the day. All right, listener, we've got a scary tale for you today. Mm-hmm. The stat is coming from visual capitalist, and the title is where AI gets its Facts from. Oh, interesting. Mm-hmm. So the most cited sources, so top 10 domain cited by large language models. So chat, GPT, all the other ones. Yeah.

All right. I am gonna go 10 to one. So number 10, open stream map.com. Never heard of it. Same Mapbox, never heard of it. TripAdvisor?

Dan Gentry: Mm-hmm.

Charles Jelen: Amazon. Okay. Facebook, Yelp, Google, YouTube. Wikipedia. The number one most cited, fact-based site is Reddit. So

Dan Gentry: doesn't this sound a little concerning? I mean, you do see these things like people send post, uh, of like bad AI results or whatever, and it's like, well, I'm guessing if you're pulling like Wikipedia and Reddit as your top two,

Charles Jelen: I personally use Wikipedia as like a fact base, especially, you know, what I use it for the most is years of albums.

Oh, well, I, yes, and it does a really good job of like discography for bands. That's, I, I,

Dan Gentry: I do the same like for movies, you know, like, like a, yeah. Cast or whoever did this thing.

Charles Jelen: Yeah. Oh, for sure. Okay. Okay. Anyways,

so there's your stat of the day. Thanks for listening to this episode of Cool Air Hot Takes. Thank you so much, Mike Firo for coming on and talking to us today. Thank you to the cool Air Hot Takes production team. Thank you, Elena. Bailey, Ainsley, Katie and Christie, you guys are awesome. Thank you.

Dan Gentry: A heads up, this is a wrap for season two, so thank you everybody for joining us on this Wild Ride.

We can confirm this is good news that season three will be back in a few weeks, so keep your eyes open and looking at your feeds for that to drop. And as always, in the meantime, you can keep sending us your questions, comments, hot. Takes. Leave us a comment on Spotify or YouTube. Leave us a review on Apple.

Drop us a message@coolair.hot takes@trane.com. And don't forget, you can always leave us a five star rating wherever you listen. And until next time, stay cool and keep those takes hot.