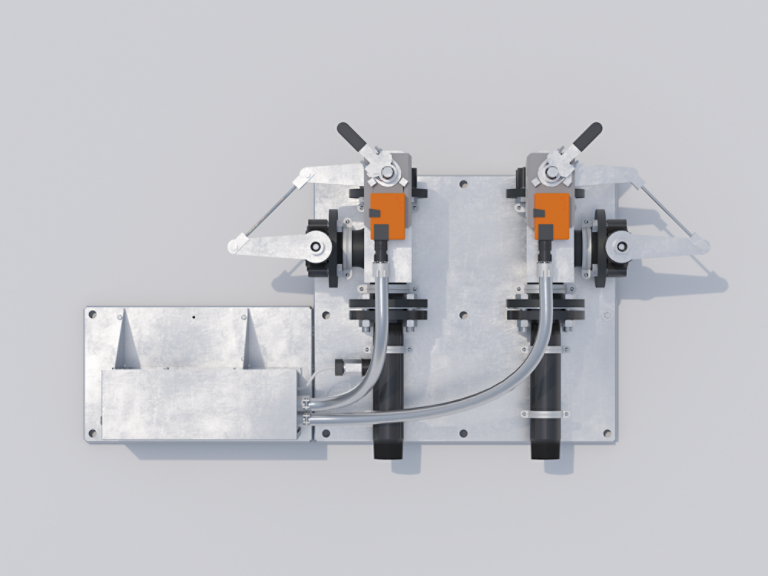

- A single, high-capacity coil enhances zone comfort and efficiency

- Central four-pipe hydronic distribution provides simultaneous cooling and heating capability year-round

- Directs the flow of hot or cold water to a thermal area based on changing needs

- Self-contained controller, preprogrammed with sequence of operation

- Butterfly valves, with 0% leakage, wired back to the controller

- Area branches only require two pipes

- 105°F or lower hot water

Hydronic Branch Conductor

Overview

Energy-efficient, year-round zone comfort from new and existing air handlers with hydronic heat pump systems.

- Simplifies zone comfort by using the same branch piping for cooling and heating.

- Adapts to changing heating and cooling loads, area by area, as needed during the same day.

- Enhances energy efficiency by heating spaces effectively with milder hot water temperatures.

- Use in retrofits (two- or four-pipe buildings) or new buildings with chilled water terminal units.

-

Load-Responsive Zone Comfort Management

Each hydronic branch conductor directs the flow of hot or cold water to a thermal area. It adapts to changing heating and cooling loads, area by area, as needed throughout the day. By utilizing milder hot water supply temperature, the conductor enables steadier supply-air temperatures—no more cycling on/off with very hot air.

.

-

Enhanced sustainability benefits

Trane's hydronic branch conductor delivers a 35% efficiency gain by heating adequately with milder, 105°F or lower hot water. This prevents system energy waste by stopping adjacent zones from fighting with each other over temperature set points. Plus, conductors integrate easily with building automation systems for enhanced energy management.

-

Reduced installation cost and complexity

With the hydronic branch conductor, retrofits repurpose existing branch cooling supply and return water piping for both heating and cooling distribution. In new construction, 50% fewer coils, valves, piping and joints reduce cost and labor. Logic for distributing hot or cold fluids into zones is built into the conductor controls, saving time for technicians.

Product Information

Trane Hydronic Branch Conductor For Electrified Heating Systems

Product Literature

Application Guides

Resources & Insights

Knowledge is the power to do more.

FAQs

Your questions about hydronic branch conductors, answered.

The hydronic branch conductor is for use in systems where the hot water and chilled water are the same fluid. There is not a mixing of fluids with different chemistry as it is the same fluid.

When the four-pipe distribution is fed by a heat pump plant where the heating fluid and cooling fluid are the same, the same piece of equipment (heat pump) is doing the cooling. If mixing of fluids is not allowed, heat exchangers may be used to isolate the loops.

If going from a heating system designed with a 30F DT (140F Hot water supply / 110 Hot water return) to a heating system with a 15F DT (105F Hot Water Supply / 90F Hot Water Return) the flow required will double. This could more than double the required pump energy.

However, this amount of pump energy is very small compared to the compressor energy (heat pump). Compressor power is more than a 10 times factor larger than the pump power. Accounting for the extra pump energy, using how water supply temperature in the 100 to 105F range will still save 30-45% in heating energy versus heating with water in the 130 to 140F range.

Select components in both loops to be rated for the higher-pressure condition, that way when the HBC operates, no components exceed their pressure rating. A pressure reducing valve (PRV) can be selected for the higher-pressure value so it will not actuate upon the hydronic branch conductor cycling.

OR

Add a pressure reducing device, such as a reducer or isolation HX to the higher pressure loop, on the source side of the hydronic branch conductor so that pressure variations when hydronic branch conductor cycles do not cause PRV nuisance trips. Note some PRVs require flow to maintain pressure.

While 6-way valves offer control for individual fan coil units with dual purpose coils, they come with higher costs, potential leakage issues, and greater installation complexity.

On the other hand, hydronic branch conductors provide a more cost-effective, efficient, and flexible solution for various equipment with dual purpose coils with standard controls, no leak valves, and simpler 2-pipe branch piping. This makes hydronic branch conductors a more attractive option for many applications, particularly where installation simplicity and cost efficiency are priorities.

Here's a more detailed look at each component.

6-Way Valves:

- Individual Control Valves: Each fan coil unit requires its own 6-way valve, necessitating a full 4-pipe branch piping system. This setup can be complex and space-consuming.

- Custom Controls and DDC Requirements: These valves often require custom controls and an analog control signal from a Direct Digital Control (DDC) controller, adding to complexity and cost.

- Leak Potential: One significant drawback is the potential for leakage from one side of the valve to the other, which can compromise system efficiency and reliability.

- Size and Cost: 6-way valves are considerably larger and more expensive than conventional 2-way or 3-way valves. They may also be difficult to fit into cabinet terminal units due to their size.

- Flow Capacity: Typically, 6-way valves have a lower flow capacity (~10 GPM) compared to Hydronic Branch Conductors.

Hydronic Branch Conductor:

- Standard Controls and Flexibility: The fan coils, fan terminals or air handlers use standard controls and can be managed with a wide range of systems, from simple thermostats to advanced DDC controllers.

- No Leak Valves: The valves used in Hydronic Branch Conductors are designed to be leak-free, enhancing system reliability and efficiency.

- 2-Pipe Branch Piping: Unlike the 4-pipe system for 6-way valves, the 4-pipe system for a Hydronic Branch Conductor operates with a simpler 2-pipe branch distribution. This reduces installation complexity and cost.

- Lower Valve Cost: The cost of valves in a Hydronic Branch Conductor system is significantly lower than that of 6-way valves. Even when compared to using two 2-way valves for traditional 4-pipe units, the cost of the HBC system remains lower.

- Space Efficiency: No additional space is needed in the zone, making it a more space-efficient option.

- Higher Flow Capacity: Hydronic Branch Conductors can handle larger capacities (up to 50 GPM nominal), making them suitable for a broader range of applications.

Tracer TU is NOT required to update or reload the application on Symbio 500. The Symbio firmware can be downloaded here.

As a best practice for restoring a controller from a backup, we recommend saving a backup file of the Hydronic Branch Conductor application during installation.

The hydronic branch conductor allows for independent zone control. Adjacent zones in the same area can be in either heating or cooling mode. However, the conductor will only allow either chilled or hot water, preventing the units from working against each other and reducing system efficiency.

If an area is cool, but a zone is in heat mode:

- Zone will not get hot water, BUT…

- Can use space load to heat

- Terminal unit can run to even air temperature distribution

- Desired system effect by balancing occupant comfort with energy efficiency

If an area is in heat, but a zone is in cooling mode:

- Zone will not get cold water, BUT…

- Some systems could use cool DOAS air to cool space (CoolSense)

- Units with mixed air can enable economizing with outdoor air when the outdoor temperature allows (<55° F)