Industry: Healthcare

Products Used: Chillers

Services Used: Energy Efficiency Contracting, Rental Services, Upgrading

Climate: Humid & Hot

Topic: Efficiency, Optimal Comfort

Challenge

Norton County Hospital’s existing chiller was more than twenty years old, and undersized for the growing facility. In addition, remodeling work completed several years ago resulted in a need for year-round cooling, which was putting an additional strain on the aging equipment. As a result, the hospital was experiencing serious comfort and reliability issues, particularly during summer months.

Solution

Dispatched from four hours away, a Trane technician quickly moved to assess the equipment failure, identified the need for new compressor parts, and contacted the Trane project manager for assistance. Knowing the urgency of the situation, the project manager quickly obtained the parts and delivered them to the hospital over the 4th of July holiday weekend. “We had been working with Trane for quite some time,” said Tyce Bruton, supervisor, Engineering Department, Norton County Hospital. “When the chiller failed, their service department helped to keep us running at half capacity.”

With the urgent issues resolved, Trane met with hospital administrators in-person on the following Sunday to discuss a long-term solution to the facility’s equipment reliability issues. After talking through the condition of the compressor, the benefits of upgrading to a more environmentally-friendly refrigerant, and the cost of repairing or replacing the equipment, it was agreed that it made more sense to install a new chiller. “We had already been looking to do a remodel of the hospital systems. We knew what we needed and Trane had evaluated chiller options,” said Bruton. “It was time to bring it to the board.” Upon board approval, the hospital and Trane moved forward with the upgrade.

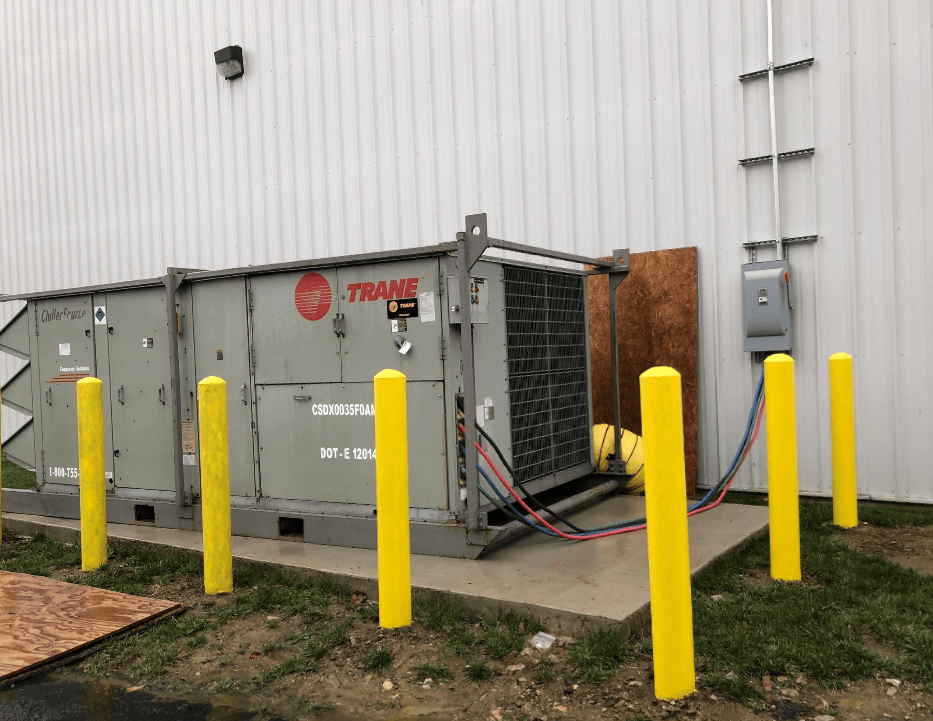

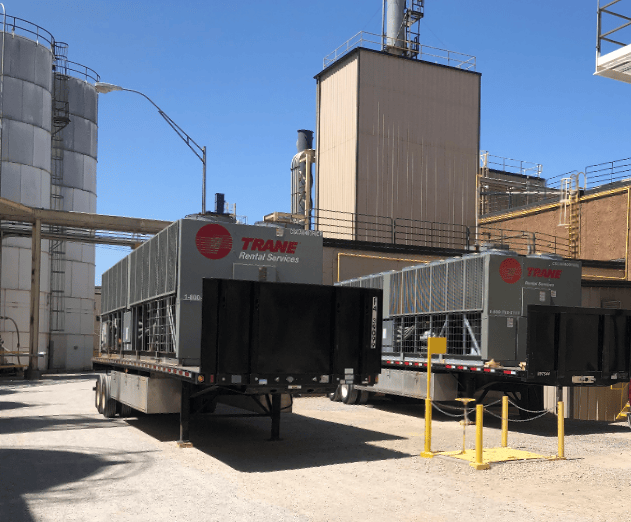

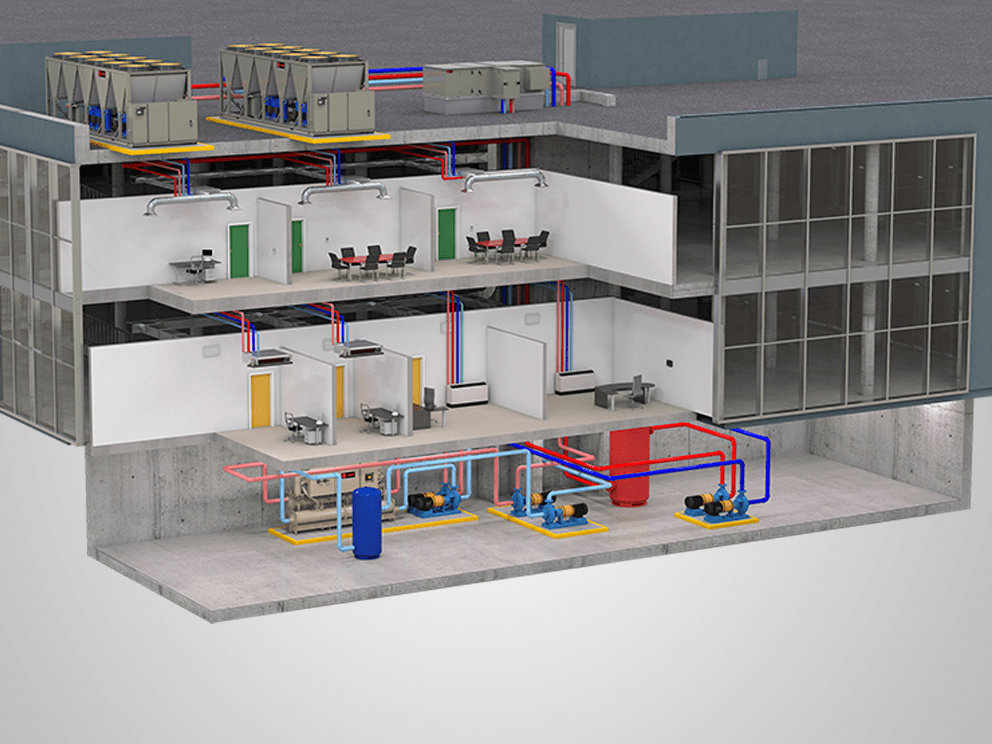

Implementing a temporary solution

To address the hospital’s immediate needs, the Trane project manager visited the jobsite to outline a plan of action. A small Trane Rental Services chiller was installed to work with the old unit to enable the hospital to continue operations while the new chiller was being built and installed. “Our old unit was still running at partial capacity,” said Frack. “We rented a smaller capacity temporary chiller and tied it into the existing unit to keep our patients and staff comfortable.”

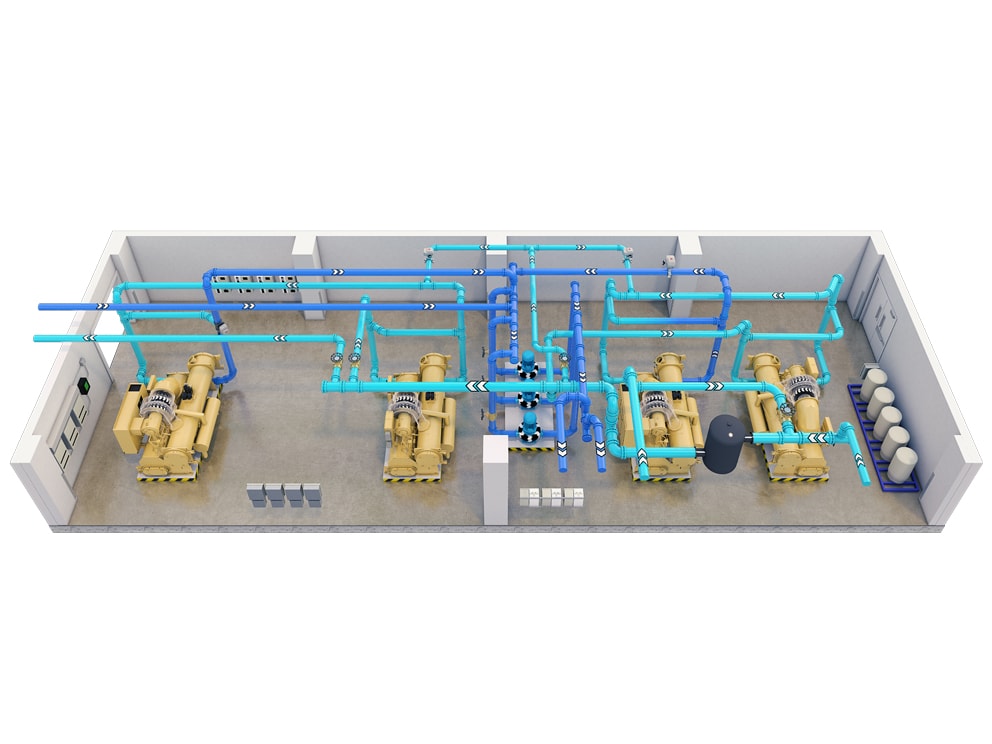

Improving reliability, control and comfort

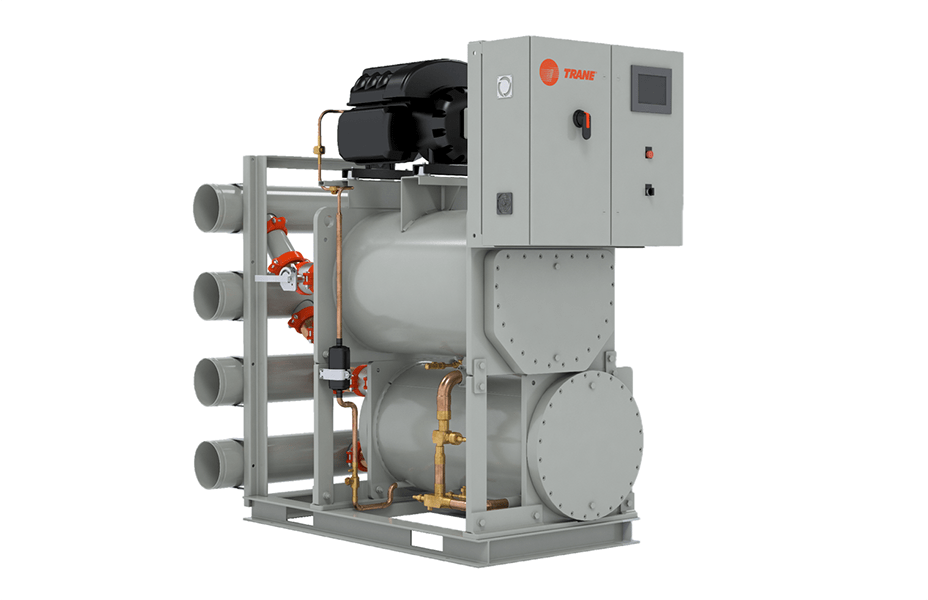

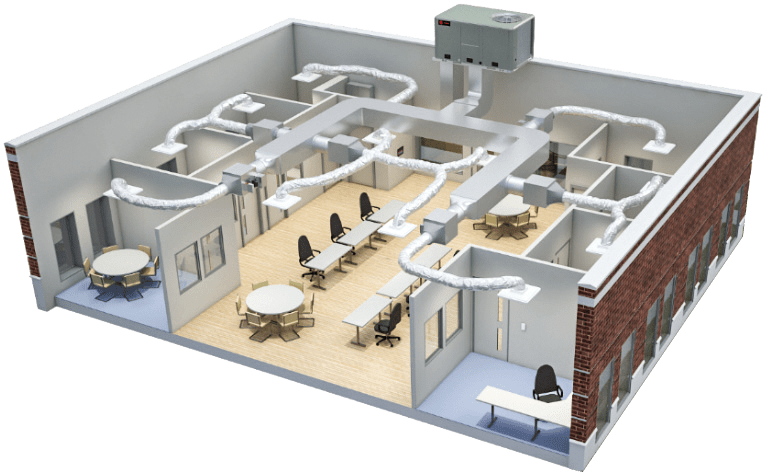

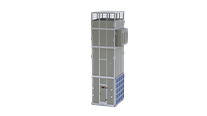

To meet the hospital’s capacity needs, a larger 200-ton air-cooled Trane Series RTM Helical Rotary Chiller was installed. The energy efficient Trane chiller provides reliability through design simplicity with few moving parts and a direct drive, low speed semi-hermetic compressor, which can restart in as little as 60 seconds to keep critical hospital operations running in the event of a power outage. Series R chillers and compressors are extensively tested during manufacturing to ensure reliable operation over a wide range of operating conditions. The Trane Series R chiller uses a more environmentally-friendly refrigerant and its efficient design provides a lower cost of ownership. In addition, the chiller controls support open protocols without the need of gateways, reducing the complexity and cost of integration with other building control systems. “It’s a better chiller design,” said Bruton. “Plus, the extra capacity helps to keep the building comfortable when temperatures get really hot.”

“Our old chiller was from 1997,” said Frack. “New technology is far more efficient, much quieter, and we have a lot more ability to control the new unit.”

Coordinating installation to put patient needs first

Quality patient care was first and foremost in the minds of hospital administrators and Trane as they worked together to schedule the chiller installation with minor disruption to hospital operations. Critical areas such as lab and x-ray services had to be suspended during the installation and some employees had to be evacuated as the chiller was lifted in overhead. The emergency room entrance also had to be closed for safety, requiring visitors to be rerouted through the front entrance. Collaborating with department heads, the team established an allowable window of time for the lab and x-ray to be down. With the Trane project manager leading the process, the crew moved quickly to complete the project within the allotted time, even as installation was halted multiple times to treat patients in need. Once installed, a Trane start-up technician was on site to immediately initiate chiller operation, ensure it was operating per design, and establish a baseline for performance and energy consumption.

“We pushed to get it done quickly so we wouldn’t have to pay for the rental unit longer than necessary,” said Frack. “Everything was planned in advance. Trane let us select the day based on our volumes and schedules. We communicated the plan to our staff, and told the public what to expect and when.”

“We closed off the parking, brought the crane in, removed the old equipment and lifted the new chiller into place,” said Bruton. “Installation went amazingly smooth.”

Ensuring optimal chiller performance

In order to reduce the risk of unplanned downtime and maximize the life of their new investment, the hospital chose a five-year Trane Service Agreement. Under the agreement factory-authorized service professionals effectively maintain and monitor chiller performance to ensure reliable operation to keep critical functions up and running. Servicing needs on a systematic basis rather than reacting to urgent emergency repairs also helps the hospital to reduce operating costs.

Results

Trane rental services, upgraded equipment, project management and service helped Norton County Hospital lower operational costs, increase chiller capacity, improve system reliability and enhance comfort. “Comfort is important and I’ve gotten positive comments from staff members regarding the improvements,” said Frack. “But the most important benefits that we’ve achieved with the chiller upgrade are the reliability, and the peace-ofmind of knowing that we’ve reduced our risk of a chiller failure.”